Automotive exhaust emissions are a major contributor to air pollution, releasing harmful volatile organic compounds (VOCs), hydrocarbons (HC), carbon monoxide (CO), and other toxic substances into the atmosphere. To address this challenge, industries and regulatory bodies rely on advanced emission control technologies—among which Regenerative Thermal Oxidizers (RTO) stand out as a highly efficient solution. But what exactly is RTO for automotive exhaust emissions? How is it made, what materials does it use, and why does its design vary? In this comprehensive guide, we answer all these questions and more, while introducing Zhongci Environmental Ceramics Materials—your trusted manufacturer of high-quality RTO components.

1. What Is RTO for Automotive Exhaust Emissions?

RTO, short for Regenerative Thermal Oxidizer, is a state-of-the-art air pollution control device specifically engineered to treat harmful pollutants in automotive exhaust. Unlike traditional oxidizers, RTOs leverage a “regenerative” heat recovery system to minimize energy consumption while maximizing pollutant destruction. Here’s how it works:

Automotive exhaust (containing VOCs, HC, CO, and other contaminants) is directed into the RTO unit, where it passes through a bed of heat-resistant ceramic packing. The exhaust is heated to extremely high temperatures (typically 800–950°C) in a combustion chamber, causing pollutants to oxidize (chemically break down) into harmless byproducts: carbon dioxide (CO₂) and water vapor (H₂O). The key innovation of RTO lies in its ability to capture and reuse the heat generated during oxidation—up to 95% heat recovery efficiency—making it one of the most energy-efficient emission control technologies for the automotive industry.

For automotive applications, RTOs are tailored to handle the variable exhaust flow rates, temperature fluctuations, and pollutant compositions common in car manufacturing, testing, and maintenance processes.

2. Which Raw Materials Make High-Quality Automotive Exhaust RTO?

The performance and durability of an automotive exhaust RTO depend largely on its core component: ceramic packing. Ceramic materials are ideal for RTOs due to their exceptional heat resistance, chemical inertness, low thermal conductivity, and structural stability—critical properties for withstanding the extreme temperatures and corrosive gases in exhaust treatment. At Zhongci Environmental Ceramics Materials, we use premium raw materials to ensure our RTO ceramic packing meets the highest industry standards:

- Cordierite (2MgO·2Al₂O₃·5SiO₂): The most widely used material for RTO ceramic packing. Cordierite offers excellent thermal shock resistance (can withstand rapid temperature changes without cracking), low thermal expansion, and high mechanical strength. It is particularly suitable for automotive RTOs, where exhaust temperatures can fluctuate sharply during vehicle testing or manufacturing cycles.

- Mullite (3Al₂O₃·2SiO₂): A high-alumina ceramic material with superior heat resistance (up to 1700°C) and corrosion resistance. Mullite-based RTO packing is ideal for high-temperature automotive exhaust applications, such as engine testing facilities or heavy-duty vehicle manufacturing plants.

- Alumina (Al₂O₃): Known for its exceptional hardness, wear resistance, and chemical stability. Alumina ceramic packing is used in RTOs handling exhaust with high levels of abrasive particles (e.g., from metalworking in automotive parts manufacturing).

- Auxiliary Materials: To enhance performance, we add high-purity binders (e.g., kaolin, bentonite) and sintering aids (e.g., zirconia, titania) during production. These materials improve the cohesion of ceramic particles, reduce sintering temperature, and enhance structural integrity.

3. How Is Automotive Exhaust RTO Manufactured? Step-by-Step Process

The manufacturing of automotive exhaust RTO ceramic packing is a precision-driven process that requires advanced equipment and strict quality control. At Zhongci Environmental Ceramics Materials, our production process follows these key steps:

1. Raw Material Preparation & Blending

First, we select and inspect raw materials (cordierite, mullite, alumina, etc.) to remove impurities (e.g., dust, metal particles). The materials are then crushed into fine powders (200–400 mesh) using high-speed crushers. Next, the powders are mixed with precise ratios of binders, sintering aids, and water in a twin-screw mixer. This blending process ensures uniform distribution of components, which is critical for consistent thermal and mechanical properties.

2. Shaping (Forming)

The blended mixture is shaped into the desired RTO packing geometry (e.g., honeycomb, saddle ring, sphere). Common forming methods include:

- Extrusion Molding: Used for honeycomb-shaped packing. The mixture is forced through a die with a honeycomb pattern using an hydraulic extruder, creating continuous ceramic profiles.

- Compression Molding: Ideal for spherical or saddle-shaped packing. The mixture is placed into a mold and pressed under high pressure (10–30 MPa) to form the desired shape.

- Injection Molding: Used for complex geometries. The mixture is heated and injected into a precision mold, allowing for intricate designs with tight tolerances.

3. Drying

The shaped ceramic green bodies (unfired products) contain moisture from the blending process. They are dried to remove excess water, preventing cracking during sintering. Drying methods include:

- Natural Air Drying: For small batches, green bodies are air-dried at room temperature for 24–48 hours.

- Tunnel Drying: For large-scale production, green bodies are passed through a temperature-controlled tunnel dryer (50–120°C) for 8–12 hours, ensuring uniform moisture removal.

4. Sintering (Firing)

Sintering is the most critical step, as it transforms the green body into a dense, heat-resistant ceramic. The dried products are placed in a high-temperature kiln (electric or gas-fired) and heated to 1200–1600°C, depending on the raw material composition. During sintering:

- Ceramic particles bond together (sintering), increasing density and strength.

- Organic binders burn off, leaving a pure ceramic structure.

- Crystalline phases form (e.g., cordierite or mullite crystals), enhancing thermal stability.

The sintering process is carefully controlled—heating and cooling rates are adjusted to avoid thermal shock, and kiln atmosphere (oxidizing or neutral) is optimized to prevent material degradation.

5. Post-Processing & Quality Inspection

After sintering, the ceramic packing undergoes post-processing:

- Trimming: Removing excess material or irregular edges using diamond tools.

- Cleaning: Removing dust or debris with compressed air or ultrasonic cleaning.

Quality inspection is conducted at every stage, but final testing includes:

- Dimensional accuracy (using calipers and laser scanners).

- Thermal shock resistance (heating to 800°C, quenching in water, repeating 10x).

- Compressive strength (testing with a universal testing machine).

- Chemical composition (using XRF spectrometry).

4. What Is the Role of RTO in Automotive Exhaust Emissions?

Automotive exhaust RTO plays three core roles in emission control, making it indispensable for the automotive industry:

1. Pollutant Destruction (Primary Function)

The primary purpose of RTO is to destroy harmful pollutants in automotive exhaust. By heating exhaust to 800–950°C, RTOs oxidize VOCs (e.g., benzene, toluene, xylene from paint and coatings), HC (unburned hydrocarbons), and CO (carbon monoxide) into CO₂ and H₂O—substances that are non-toxic and compliant with global emission standards (e.g., EPA, EU Euro 7, China GB/T 30512). Destruction efficiency (DRE) typically exceeds 99%, ensuring automotive facilities meet strict regulatory requirements.

2. Energy Recovery (Cost Savings)

Unlike conventional thermal oxidizers, which waste most of the heat generated during oxidation, RTOs capture and reuse this heat. The ceramic packing acts as a heat exchanger: during the “oxidation cycle,” the ceramic bed absorbs heat from the hot, treated exhaust. In the next cycle, the preheated ceramic bed transfers heat to the incoming cold exhaust, reducing the need for additional fuel (e.g., natural gas) to reach oxidation temperature. This heat recovery can reduce energy costs by 70–90% compared to non-regenerative oxidizers, making RTO a cost-effective long-term solution.

3. Long-Term Stability & Low Maintenance

Automotive RTOs are designed for continuous operation (24/7) in harsh industrial environments. The ceramic packing’s heat resistance and chemical inertness ensure the unit can withstand high temperatures, corrosive gases, and thermal cycling without degradation. With proper maintenance (e.g., periodic cleaning of ceramic packing), RTOs have a service life of 10–15 years, requiring minimal replacement of components. This reliability is critical for automotive manufacturing plants, where downtime can lead to significant production losses.

https://chempacking.cn/wp-content/uploads/2024/10/1643250330521678.jpg

5. Why Do Automotive RTO Units Have Different Shapes? Key Differences

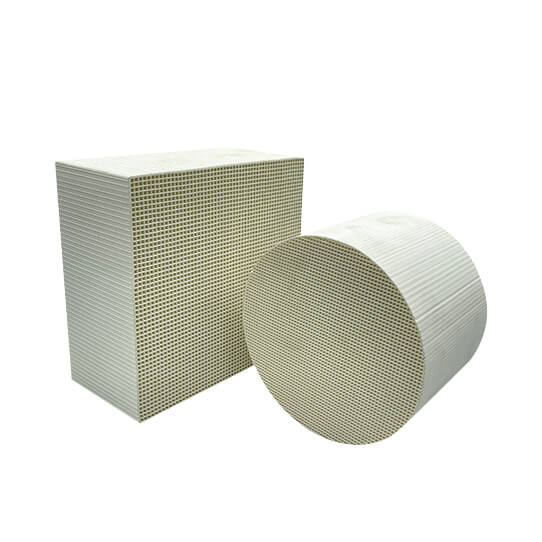

Automotive exhaust RTO ceramic packing comes in various shapes, each designed to optimize performance for specific applications. The shape affects key parameters such as surface area, pressure drop, heat transfer efficiency, and resistance to clogging. Below are the most common shapes and their differences:

1. Honeycomb-Shaped RTO Packing

- Design: Hexagonal or square cells arranged in a honeycomb pattern, with high cell density (100–400 cells per square inch).

- Advantages:

- Maximum surface area (critical for heat transfer and pollutant oxidation).

- Low pressure drop (minimizes energy consumption for exhaust fan operation).

- Uniform gas distribution, ensuring consistent pollutant destruction.

- Disadvantages: Susceptible to clogging if exhaust contains high levels of dust or particulate matter.

- Best For: Automotive paint shops, coating facilities, and engine testing labs (low-dust exhaust, high flow rates).

2. Saddle Ring (Intalox Saddle) RTO Packing

- Design: Irregular, saddle-like shape with curved surfaces and open structure.

- Advantages:

- Excellent 透气性 (gas permeability), reducing clogging risk for dusty exhaust.

- High turbulence, enhancing heat transfer and pollutant mixing.

- Self-supporting structure, easy to pack and replace.

- Disadvantages: Higher pressure drop compared to honeycomb packing.

- Best For: Automotive parts manufacturing (e.g., metal stamping, welding) and recycling facilities (high-dust exhaust).

3. Spherical RTO Packing

- Design: Smooth, spherical ceramic beads (5–20 mm diameter).

- Advantages:

- Uniform packing density, ensuring consistent gas flow.

- Low wear and tear (smooth surface reduces friction between particles).

- Easy to clean and replace.

- Disadvantages: Lower surface area than honeycomb or saddle ring packing.

- Best For: Small-scale RTO units (e.g., auto repair shops) or applications with moderate pollutant loads.

4. Corrugated RTO Packing

- Design: Corrugated sheets of ceramic, stacked to create a zigzag flow path.

- Advantages:

- High heat transfer efficiency (corrugated structure increases turbulence).

- Compact design, saving space in RTO units.

- Balanced surface area and pressure drop.

- Disadvantages: Less resistant to clogging than saddle ring packing.

- Best For: Compact RTO systems (e.g., electric vehicle battery production facilities) with limited installation space.

At Zhongci Environmental Ceramics Materials, we offer all these shapes and can customize RTO packing dimensions (size, cell density, thickness) to match your specific automotive exhaust treatment needs.

6. Where Are RTO Systems Used for Automotive Exhaust Treatment?

Automotive exhaust RTO systems are widely used across the automotive industry, wherever harmful emissions are generated. Key applications include:

1. Automotive Manufacturing Plants

- Paint Shops & Coating Lines: The largest source of VOC emissions in automotive manufacturing. RTOs treat exhaust from spray booths, curing ovens, and primer/paint application processes, destroying VOCs from automotive paints, adhesives, and sealants.

- Engine & Transmission Production: Exhaust from machining, degreasing, and heat treatment processes contains HC and CO. RTOs ensure compliance with emission regulations while recovering heat for process heating.

- Body Assembly Plants: Emissions from welding fumes, adhesive curing, and surface treatment are treated with RTOs to protect worker health and the environment.

2. Engine Testing Facilities

- Automotive OEMs and aftermarket suppliers test engines for performance and durability, generating high-temperature exhaust with HC, CO, and NOₓ. RTOs handle variable exhaust flow rates and destroy pollutants before release.

3. Auto Repair & Maintenance Shops

- Large repair facilities (e.g., fleet maintenance centers) generate exhaust from engine tuning, emissions testing, and repair work. Compact RTO units treat these emissions to meet local air quality standards.

4. Automotive Parts Manufacturing

- Suppliers of components (e.g., tires, plastic parts, metal components) generate emissions from molding, extrusion, and surface finishing. RTOs ensure these facilities comply with industrial emission regulations.

5. Electric Vehicle (EV) Production Facilities

- EV battery manufacturing (lithium-ion battery production) generates VOCs from electrolytes, binders, and solvents. RTOs treat these emissions, supporting the green transition of the automotive industry.

6. Automotive Recycling Facilities

- Scrap yards and vehicle recycling plants generate emissions from shredding, melting, and paint stripping. RTOs destroy harmful pollutants, making recycling processes more environmentally friendly.

7. Why Is Steel Cladding Applied to Automotive Exhaust RTO?

Many automotive exhaust RTO units feature a layer of steel cladding (铁皮) around the ceramic packing and combustion chamber. This design choice serves six critical purposes:

1. Heat Insulation (Energy Conservation)

RTOs operate at extremely high temperatures (800–950°C). Steel cladding, combined with insulation materials (e.g., ceramic fiber, rock wool) between the steel and ceramic packing, minimizes heat loss to the surrounding environment. This improves heat recovery efficiency, reduces fuel consumption, and lowers operating costs.

2. Protection of Ceramic Packing

Ceramic packing is brittle and susceptible to damage from physical impact (e.g., during installation, maintenance, or transportation). Steel cladding acts as a protective shell, preventing cracks or breakage of the ceramic core—extending the lifespan of the RTO unit.

3. Structural Stability

Steel cladding provides mechanical support to the RTO unit, especially for large-scale systems. It reinforces the structure, preventing deformation under high temperatures and ensuring the ceramic packing remains properly aligned for optimal gas flow and heat transfer.

4. Safety (Preventing Burns)

The external surface of an unclad RTO unit can reach temperatures exceeding 200°C, posing a burn hazard to workers. Steel cladding, combined with insulation, keeps the external surface temperature below 60°C, ensuring workplace safety.

5. Corrosion Resistance

Automotive facilities are often humid or expose RTO units to corrosive substances (e.g., cleaning chemicals, moisture in exhaust). Steel cladding (typically galvanized or stainless steel) resists corrosion, protecting the internal ceramic components and extending the RTO’s service life.

6. Noise Reduction

RTO units generate noise from exhaust fans and combustion processes. Steel cladding, along with insulation, acts as a sound barrier, reducing noise pollution in the workplace.

8. Choose Zhongci Environmental Ceramics Materials for Your Automotive Exhaust RTO Needs

When it comes to automotive exhaust RTO systems, the quality of ceramic packing directly impacts performance, energy efficiency, and compliance. At Zhongci Environmental Ceramics Materials, we specialize in manufacturing high-performance ceramic packing for RTO units, tailored to the unique demands of the automotive industry.

Our advantages:

Premium Raw Materials: We use high-purity cordierite, mullite, and alumina to ensure exceptional heat resistance, thermal shock resistance, and durability.

Customized Solutions: We offer a full range of shapes (honeycomb, saddle ring, spherical, corrugated) and can customize dimensions, cell density, and thickness to match your RTO system’s requirements.

Energy Efficiency: Our RTO ceramic packing is designed for maximum heat recovery (up to 95%), reducing your operating costs.

Global Support: We serve customers worldwide, providing technical consultation, installation guidance, and after-sales support.

Whether you’re building a new RTO system for an automotive manufacturing plant, upgrading an existing unit, or need replacement ceramic packing, Zhongci has the expertise and products to meet your needs.

Contact Us Today

For more information about our automotive exhaust RTO ceramic packing, to request a quote, or to discuss your specific application, visit our official:http://www.chempackings.com

Our team of environmental materials experts is ready to help you find the perfect solution for emission control and energy savings.