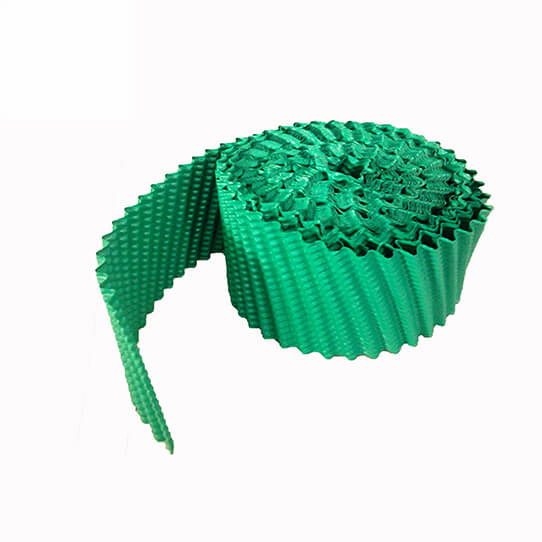

Cooling tower fill media (also called splash fill, film fill, or water distribution filler) is one of the core internal components inside cooling towers. Its function is to increase the heat transfer surface area between water and air so that the tower can cool circulated industrial water more efficiently.

When hot water enters the cooling tower, it is sprayed onto the fill. The fill spreads the water into thin layers, droplets, or splashes, greatly enlarging the contact area with upward airflow. This enhances evaporation, heat dissipation, and cooling rate. Without proper fill, a cooling tower would lose more than 50% cooling efficiency.

1. Purpose and Working Function

Cooling tower fill improves the cooling process in four main ways:

| Function | Description |

|---|---|

| Heat Exchange | Extends time for air–water contact to maximize heat transfer |

| Water Distribution | Uniformly disperses water flow to prevent channeling or flooding |

| Evaporation Enhancement | Promotes water droplet breakup for faster heat loss |

| Energy Saving | Reduces load on pumps, fans, and circulating system |

Good quality fill lowers energy consumption, stabilizes inlet/outlet temperature, and protects the entire cooling tower system.

2. Materials of Cooling Tower Fill — Detailed Comparison

| Material | Temp Resistance | Chemical Resistance | Best For | Lifespan |

|---|---|---|---|---|

| PVC | 60–65°C | Good | Clean water HVAC systems | 5–8 years |

| PP | Up to 85°C | Excellent | High-temperature industrial cooling | 8–12 years |

| Ceramic / Honeycomb Ceramic | >1000°C | Excellent | Harsh industrial water, gas–liquid systems | 15+ years |

PVC and PP film fills are ideal for common industrial cooling.

Ceramic fill is preferred for power industry, petrochemical exhaust, high-temperature wet gas, and corrosive working conditions, where plastic fill cannot survive.

3. Where Cooling Tower Fill Is Used

Cooling tower fill is widely applied in:

- Thermal power plants

- Oil refining and petrochemical plants

- Chemical fertilizer plants

- Pharmaceutical manufacturing

- Metallurgy and steel mills

- Textile, printing & dyeing plants

- Paper mills

- HVAC cooling systems for commercial buildings

- Wastewater treatment cooling applications

Any system that needs continuous cooling of circulating water depends on fill media.

4. Standard Sizes and Technical Specifications

Cooling tower fill specifications vary depending on tower design and support frame.

Common sizes include:

| Size | Thickness | Weight | Application |

|---|---|---|---|

| 1000 × 500 mm | 0.25–0.4 mm | Light | Small HVAC cooling |

| 1200 × 600 mm | 0.25–0.6 mm | Medium | Factory cooling |

| 1350 × 1000 mm | 0.3–0.6 mm | Heavy | Power & chemical industry |

| Custom dimensions | — | — | OEM and retrofits |

For ceramic honeycomb fill, common cell structures include 13×13 mm, 25×25 mm, 40×40 mm, 50×50 mm, depending on airflow resistance and water quality.

5. How to Determine Required Fill Quantity

The exact amount is calculated based on tower internal capacity.

General calculation guideline:

Fill Volume (m³) ≈ Tower Inner Space (m³) – Spray + Drift Eliminator + Fan Space

Additional factors:

- Water temperature and flow rate

- Required cooling performance

- Water quality (clean / dirty / oily)

- Tower operating hours per year

Zhongci provides free volume calculation if tower size or engineering design is supplied.

6. Advantages of High-Quality Fill

- Higher cooling efficiency and outlet temperature stability

- Lower water and energy consumption

- Longer service life and reduced maintenance

- Prevention of clogging and biofouling

- Less risk of tower shutdown

Poor quality fill leads to tower collapse, corrosion, and massive energy waste.

https://chempacking.cn/wp-content/uploads/2024/10/1643267793890512.jpg

Conclusion

Cooling tower fill is the heart of the cooling tower. Choosing the correct type, size, and material creates significant benefits: reduced cost, longer lifespan, and stable cooling performance.

📌 Zhongci Environmental Ceramics Materials manufactures and exports ceramic, PVC, and PP cooling tower fill media worldwide, supporting custom designs, OEM sizing, and technical installation guidance.

🌐 www.chempackings.com | 📞 Whatsapp: +86 135 7645 4821