In modern chemical, petrochemical, and environmental industries, mass transfer equipment plays a crucial role in processes such as absorption, distillation, and scrubbing. The choice of packing material inside these towers directly affects efficiency, cost, and long-term performance. Among the many options available, ceramic structured packing has become one of the most reliable solutions thanks to its thermal resistance, chemical durability, and optimized surface design.

1. What is Ceramic Structured Packing?

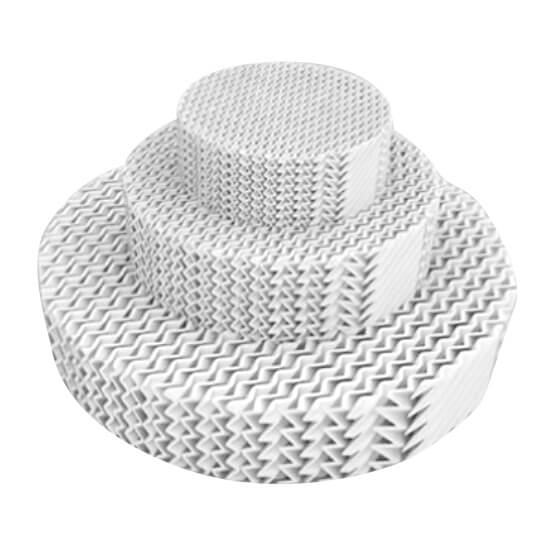

Ceramic structured packing is a regular, ordered form of tower packing composed of thin corrugated ceramic sheets stacked in a uniform arrangement. Unlike random packing (such as ceramic Raschig rings or Pall rings), structured packing offers a precisely engineered geometry that ensures predictable flow distribution, minimal channeling, and high separation efficiency.

Its design maximizes the gas-liquid contact area, allowing efficient absorption, desorption, and distillation processes. Moreover, ceramics’ natural properties—such as corrosion resistance, low thermal expansion, and mechanical strength—make ceramic structured packing particularly suitable for aggressive and high-temperature environments.

2. Raw Materials Used in Ceramic Structured Packing

High-quality ceramics are carefully formulated to produce structured packing that can withstand extreme industrial conditions. Typical raw materials include:

- Alumina (Al₂O₃): Provides strength, hardness, and resistance to wear. Alumina-rich ceramics are especially suited for high-corrosion and high-temperature conditions.

- Silica (SiO₂): Enhances chemical resistance and thermal stability.

- Kaolin and Clay: Improve workability during shaping and contribute to thermal shock resistance.

- Minor mineral additives: Adjust porosity, shrinkage, and sintering behavior for optimal performance.

The precise ratio of these materials determines whether the structured packing is general-purpose or suitable for specialized high-performance applications.

3. How is Ceramic Structured Packing Manufactured?

The production process involves multiple stages to achieve a balance between strength, porosity, and chemical durability:

- Raw Material Preparation

Minerals are finely ground, purified, and mixed into a uniform ceramic slurry or powder. - Shaping and Molding

- Corrugated sheets are formed using molds or extrusion techniques.

- These sheets are designed with specific angles (usually 45° or 60°) to create maximum gas-liquid interaction.

- Different designs allow adjustments for efficiency or pressure drop.

- Drying

Carefully controlled drying prevents cracks and preserves shape. Uneven drying could reduce mechanical strength. - Firing / Sintering

- The ceramic is fired at 1,000–1,300°C, depending on the formula.

- This step ensures structural integrity, corrosion resistance, and thermal durability.

- Assembly

The corrugated plates are stacked into blocks. Each block is engineered to fit into distillation towers, absorption columns, or scrubbing units.

Through this process, the result is a rigid yet porous ceramic block that maintains stability under demanding process conditions.

4. Key Advantages of Ceramic Structured Packing

Ceramic structured packing offers numerous benefits over random packing and even some metal or plastic alternatives:

- High Surface Area per Volume: Improves mass transfer efficiency in absorption and distillation.

- Low Pressure Drop: Ensures smooth airflow and reduces energy costs.

- Excellent Chemical Resistance: Withstands acids, alkalis, and solvents that corrode metals.

- Thermal Stability: Performs reliably at extremely high temperatures without deformation.

- Mechanical Strength: Supports long-term operation with minimal risk of breakage.

- Improved Hydrodynamics: Provides uniform liquid distribution and reduces flooding risk.

- Longevity: Extended service life compared to plastic or metal structured packing in corrosive environments.

5. Classifications of Ceramic Structured Packing

Ceramic structured packing can be categorized by geometry, size, and surface design:

- Corrugated Ceramic Structured Packing

- Features angled corrugated sheets (typically 45° or 60°).

- Offers high efficiency and is widely used for gas absorption and solvent recovery.

- Grid-Type Ceramic Packing

- Designed with large open channels.

- Excellent for processes requiring low pressure drop and high capacity.

- Perforated Ceramic Packing

- Includes small holes or texturing on the surface.

- Enhances liquid spreading and prevents channeling.

- Customized Ceramic Packing

- Tailored geometries for specialized processes such as waste gas treatment or high-viscosity liquid absorption.

Each type is chosen depending on operating conditions, column design, and efficiency requirements.

https://chempacking.cn/wp-content/uploads/2024/10/1643184030883881.jpg

6. Applications of Ceramic Structured Packing

Ceramic structured packing is indispensable in industries where high efficiency and corrosion resistance are required:

- Chemical Industry:

- Gas absorption (e.g., HCl, H₂S, SO₂ removal).

- Solvent recovery and stripping.

- Distillation of corrosive liquids.

- Petrochemical Industry:

- Acidic gas treatment in refineries.

- Dehydration and purification of solvents.

- Drying towers for corrosive or high-temperature gases.

- Environmental Protection:

- Flue gas desulfurization (FGD) in power plants.

- Waste gas scrubbing in chemical plants.

- Treatment of industrial wastewater containing volatile organic compounds (VOCs).

- Other Applications:

- Heat-resistant processes in metallurgy.

- Catalyst support structures in chemical reactors.

7. How to Choose the Right Ceramic Structured Packing

Selecting the correct type of ceramic structured packing depends on multiple factors:

- Operating Conditions

- High temperature → Choose alumina-rich packing.

- Strongly corrosive chemicals → Opt for silica-based formulations.

- Column Design

- Tall towers require low-pressure-drop packing to save energy.

- Wide columns benefit from structured packing with high surface area.

- Process Type

- Absorption processes → Corrugated packing for high efficiency.

- High-capacity stripping → Grid or perforated packing.

- Cost vs. Efficiency

- Consider both capital and operating costs.

- Higher-efficiency packing reduces long-term energy consumption.

8. Why Choose Zhongci Environmental Ceramics Materials?

At Zhongci Environmental Ceramics Materials (🌐 www.chempackings.com), we are proud to be a leading manufacturer and supplier of ceramic structured packing.

Our strengths include:

- Premium raw materials ensuring durability and resistance.

- Wide product range, including corrugated, grid, and custom-designed packing.

- Expert engineering support to help customers select the right type for their process.

- Global delivery and stable quality assurance trusted by chemical and environmental industries worldwide.

By choosing Zhongci, you gain a long-term partner committed to delivering cost-effective, efficient, and reliable ceramic solutions.