Custom Mullite Products: Complete Guide to Ordering, Specifications, and Advantages

Mullite is one of the most widely used advanced ceramics thanks to its exceptional thermal stability, resistance to corrosion, low thermal expansion, and mechanical strength at high temperatures. These qualities make it the preferred material for industries such as metallurgy, ceramics, petrochemicals, electronics, energy, and environmental protection.

However, every application has unique requirements. That is why custom mullite products are increasingly demanded by industrial users who need precise dimensions, specialized shapes, and tailored material properties.

At Zhongci Environmental Ceramics Materials (🌐 www.chempackings.com), we provide fully customized mullite solutions. Whether you need a single prototype or large-scale production, we can design, manufacture, and deliver products that meet your exact technical standards.

This guide will cover:

- Which mullite products can be customized

- What technical details to provide when placing an order

- Normal tolerance ranges for mullite manufacturing

- Why choosing our company ensures quality, reliability, and cost-effectiveness

Types of Custom Mullite Products

Mullite ceramics can be processed into a wide variety of shapes and components. The most common customized items include:

1. Mullite Tubes

- Applications: Furnace tubes, kiln tubes, thermocouple protection tubes, gas flow tubes.

- Custom Options: Outer diameter, inner diameter, length (up to 2,000 mm), wall thickness, closed or open ends.

2. Mullite Saggars (Crucibles, Boats, and Containers)

- Applications: Powder calcination, ceramic firing, metal sintering, and catalyst testing.

- Custom Options: Round, rectangular, or complex geometries; with or without lids; glazed or unglazed surfaces.

3. Mullite Plates and Trays

- Applications: Kiln furniture, support structures for firing, substrate carriers.

- Custom Options: Flat plates, multi-level trays, customized holes or slots for airflow.

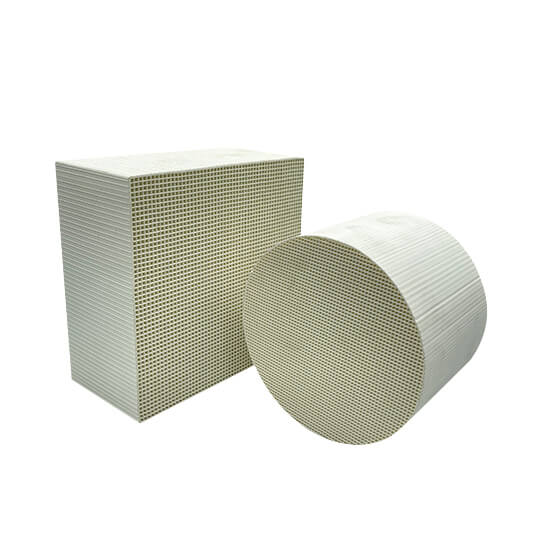

4. Mullite Honeycomb Blocks

- Applications: Catalyst carriers, regenerative thermal oxidizers (RTOs), heat exchangers, gas filtration.

- Custom Options: Cell density from 50 to 400 cpsi, wall thickness between 0.3–2 mm, rectangular or cylindrical blocks.

https://chempacking.cn/wp-content/uploads/2024/10/1710383137849495-600×600.jpg

5. Mullite Bricks and Insulating Blocks

- Applications: Furnace linings, kiln insulation, and high-temperature chambers.

- Custom Options: Different grades of density and porosity to balance insulation and strength.

6. Mullite Special Shapes and Nozzles

- Applications: Burner nozzles, gas injection parts, flow distributors.

- Custom Options: Complex 3D geometries based on CAD drawings or samples.

Information You Should Provide for Custom Mullite Orders

To guarantee that your custom mullite products meet performance requirements, it is important to provide clear specifications. The following information is typically required:

- Dimensions & Geometry

- Exact measurements (length, width, height, inner/outer diameters, wall thickness).

- Special features: holes, slots, grooves, or angled surfaces.

- Material Composition

- Mullite content (70%, 80%, or >90%).

- High-purity mullite is used for extreme thermal shock resistance.

- Working Conditions

- Maximum continuous operating temperature (typically 1,400–1,700 °C).

- Atmosphere: oxidizing, reducing, inert, vacuum, or corrosive gases.

- Frequency of heating and cooling cycles.

- Mechanical and Thermal Properties Required

- Strength requirements (compressive, bending, or tensile strength).

- Thermal expansion coefficient limits.

- Porosity or density specifications.

- Surface Treatment

- Glazed (for improved chemical resistance) or unglazed (for thermal stability).

- Surface finish: polished, semi-finished, or rough.

- Quantity & Delivery Terms

- Number of pieces required.

- Prototype or mass production.

- Preferred delivery date.

Normal Tolerances for Mullite Products

Mullite ceramics are usually manufactured with the following standard tolerance ranges:

- Length / Width / Height: ±1–2 mm

- Outer Diameter: ±1% of nominal size

- Inner Diameter: ±1.0–1.5 mm

- Wall Thickness: ±0.5 mm

- Flatness (plates & trays): ±0.5–1 mm

- Honeycomb Cell Density (cpsi): ±5%

For applications requiring extremely high precision (e.g., laboratory equipment or advanced catalytic supports), tighter tolerances can be achieved with CNC machining or isostatic pressing.

Why Choosing Our Company Matters

Selecting the right supplier is as important as choosing the right product. At Zhongci Environmental Ceramics Materials, we combine technical expertise, advanced manufacturing, and reliable service to deliver superior mullite products. Here is why customers around the world trust us:

- Extensive Product Range – From tubes and crucibles to honeycombs and complex shapes, we offer complete customization.

- Material Expertise – Our engineers help you select the correct mullite grade for your application.

- Advanced Manufacturing – Precision extrusion, isostatic pressing, and CNC finishing ensure accuracy and consistency.

- Strict Quality Control – Every product is tested for dimensional accuracy, thermal resistance, and mechanical strength.

- Flexible Customization – Small batches, prototypes, or mass production available.

- Global Supply Network – Fast delivery worldwide, with professional export packaging.

- Technical Support – We work closely with customers to optimize designs and reduce costs.

👉 If you are looking for a trusted supplier of custom mullite products, Zhongci Environmental Ceramics Materials (🌐 www.chempackings.com) is your ideal partner.