Understanding the Difference Between Heat Storage Body, Honeycomb Ceramics, and RTO Systems

In the field of industrial energy recovery, environmental protection, and exhaust gas purification, three terms often appear together — heat storage body, honeycomb ceramics, and RTO (Regenerative Thermal Oxidizer).

Although these concepts are related, they are not the same. Each plays a unique role in the process of heat exchange and waste gas treatment.

Let’s explore their definitions, materials, structures, and differences in detail.

https://chempacking.cn/wp-content/uploads/2024/10/1643250330726382-100×100.jpg

1. What Is a Heat Storage Body (Regenerative Ceramic)?

A heat storage body, also known as a regenerative ceramic, is a type of high-temperature-resistant ceramic component used to store and release heat. It is mainly applied in industrial furnaces, regenerative burners, and RTO systems to improve energy efficiency.

✅ Key Features:

- Function: Stores heat from exhaust gas and releases it back into the combustion air, improving thermal efficiency.

- Structure: Often designed as balls, honeycomb blocks, or perforated bricks to increase surface area for heat transfer.

- Working Principle:

During operation, the hot gas passes through the ceramic media, heating it up. When the gas flow reverses, the stored heat is transferred to the incoming cold air or gas stream. - Common Materials:

- Cordierite (2MgO·2Al₂O₃·5SiO₂)

- Corundum-mullite

- Alumina ceramics

- Silicon carbide (SiC)

These materials are selected for their high thermal shock resistance, excellent heat capacity, and long service life.

⚙️ Applications:

- Regenerative burners in steel, glass, and ceramic industries

- RTO and RCO systems for VOC abatement

- Heat exchangers and thermal storage units

🌡️ Advantages:

- Increases furnace energy efficiency by up to 30–60%

- Reduces fuel consumption and CO₂ emissions

- Long lifespan and stable thermal performance

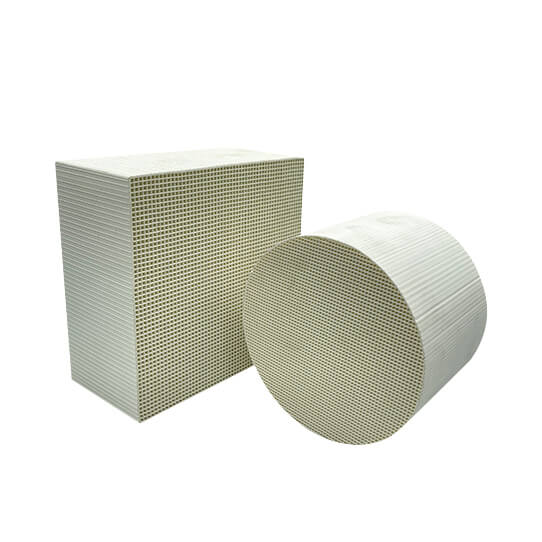

2. What Is Honeycomb Ceramic?

Honeycomb ceramics are structural ceramics characterized by a multi-channel honeycomb shape.

They are designed for efficient heat transfer, gas flow, and catalyst loading.

While honeycomb ceramics can also serve as heat storage media, they are broader in application and may serve as catalyst supports, filters, or substrates.

✅ Key Features:

- Structure: Thousands of straight, parallel channels (square or hexagonal) that allow smooth gas passage with minimal pressure drop.

- Material:

- Cordierite (most common due to low thermal expansion)

- Alumina

- Mullite

- Silicon carbide (SiC)

- Manufacturing Process: Extrusion molding → drying → firing at high temperatures.

⚙️ Applications:

- Catalytic converter substrates in automobiles

- Diesel particulate filters (DPF)

- RTO/RCO heat exchange media

- Gas and liquid filtration

- Exhaust gas purification systems

🌡️ Advantages:

- High specific surface area for efficient reaction or heat transfer

- Low thermal expansion → excellent thermal shock resistance

- Lightweight and durable

- Stable under high temperatures (up to 1400°C)

3. What Is an RTO (Regenerative Thermal Oxidizer)?

An RTO, or Regenerative Thermal Oxidizer, is not a ceramic material, but an industrial system or device used for purifying VOCs (volatile organic compounds) and other hazardous gases by oxidizing them at high temperatures.

Inside an RTO, heat storage ceramics or honeycomb ceramics are used as the core heat exchange media.

✅ Working Principle:

- Polluted air enters the RTO system.

- The gas passes through ceramic heat storage beds, which preheat it using stored energy.

- The gas is then heated in a combustion chamber (typically 800–1000°C), where VOCs are oxidized into CO₂ and H₂O.

- The hot, clean gas then passes through another ceramic bed, transferring its heat to be reused for the next cycle.

⚙️ Components of RTO:

- Ceramic heat storage media (balls or honeycomb)

- Combustion chamber

- Switching valves

- Exhaust ducts and fans

🌍 Applications:

- Chemical industry VOC treatment

- Paint and coating waste gas purification

- Printing and packaging exhaust control

- Pharmaceutical and electronic manufacturing emissions reduction

🌡️ Advantages:

- VOC destruction efficiency ≥ 99%

- High thermal energy recovery (up to 95%)

- Low operating cost and energy consumption

- Eco-friendly solution for air pollution control

4. The Differences Between Heat Storage Body, Honeycomb Ceramics, and RTO

| Item | Heat Storage Body | Honeycomb Ceramic | RTO (Regenerative Thermal Oxidizer) |

|---|---|---|---|

| Type | Material/Component | Material/Structure | Equipment/System |

| Main Function | Store and release heat | Heat exchange, catalysis, filtration | Purify exhaust gases (VOCs) |

| Shape/Form | Balls, perforated blocks, honeycomb | Honeycomb with parallel channels | Large system with multiple chambers |

| Material | Cordierite, alumina, mullite, SiC | Cordierite, SiC, mullite | Contains ceramics inside |

| Application | Burners, furnaces, RTO | Catalytic converters, filters, RTO | Industrial VOC treatment |

| Temperature Resistance | 1000–1700°C | 800–1400°C | Operates around 800–1000°C |

In short:

- The heat storage body is a component used to store thermal energy.

- The honeycomb ceramic is a structural medium that can serve as a heat storage body or catalyst support.

- The RTO is a complete system that uses ceramics (like honeycomb or spherical heat storage media) to recover heat and treat exhaust gas.

https://chempacking.cn/wp-content/uploads/2024/10/1643250330521678-100×100.jpg

5. How to Choose the Right Material

When selecting ceramic media for heat storage or RTO systems, consider:

| Requirement | Recommended Material |

|---|---|

| High heat capacity, low cost | Cordierite |

| High strength, corrosion resistance | Mullite |

| High temperature (above 1300°C) | Alumina |

| Fast heat exchange, oxidation resistance | Silicon Carbide (SiC) |

6. Zhongci Environmental Ceramics — Your Reliable Supplier

Zhongci Environmental Ceramics Materials (www.chempackings.com ) specializes in producing high-quality ceramic media, including:

- Heat storage ceramic balls

- Honeycomb ceramics

- Ceramic saddles and packings

- Ceramic filter materials

Our products are widely used in RTO, RCO, petrochemical, metallurgy, and environmental protection industries, offering excellent heat resistance, high efficiency, and long-term durability.

We can provide customized shapes, materials, and specifications according to customer needs.