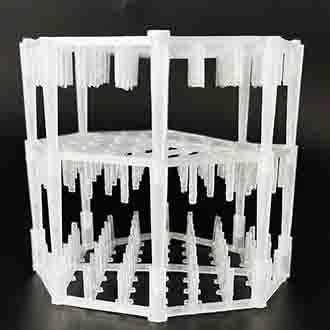

“Octagonal Plastic Q-Pack Tower Packing” (often called “Plastic Q-Pack” or “Q-PAC / Q-PACK” random packing) is a high-performance random packing element used in packed towers, scrubbers, absorbers, gas-liquid contactors, water treatment columns, and similar mass-transfer equipment. It is characterized by an octagonal / bar-and-rod / “Q-shaped” geometry and is made of engineering plastics that exhibit good chemical and thermal resistance.

Because of its design, Q-Pack offers a large open structure (high voidage), relatively low pressure drop, excellent gas–liquid contacting surface, and resistance to fouling.

In short: it is a kind of plastic random packing optimized for high-efficiency transfer in scrubbers / towers.

1. Raw Materials & Construction / Manufacturing Process

Common Materials

Plastic Q-Pack is typically manufactured from one or more of the following thermoplastic materials:

| Material | Key Properties | Typical Use / Limitation |

|---|---|---|

| PP (polypropylene) | Good chemical resistance, relatively low cost, moderate temperature tolerance (≈ 80–100 °C) | Widely used in standard applications |

| PE (polyethylene) | Good toughness and low cost, but lower chemical/temperature resistance than PP | Used in milder conditions |

| RPP (reinforced polypropylene) | Enhanced mechanical strength, perhaps with fillers or reinforcements | For more demanding mechanical or load-bearing applications |

| PVC / CPVC | Better chlorine / acid resistance; CPVC offers higher-temperature capability | In moderately corrosive / chlorinated environments |

| PVDF (polyvinylidene fluoride) | Highest chemical and temperature resistance among typical options | For harsh environments, acidic gases, or high temperature service |

2. Structural Design & Geometry

The Q-Pack geometry typically comprises a bar-and-rod framework, forming an octagonal outer cross section and internal rods or drip points to enhance liquid distribution.

The design aims to maximize void fraction (i.e. open space for vapor or gas flow) — typical voidage is ~96.3 %.

It also aims to maximize gas-liquid contact surface area while minimizing pressure drop. In metric units, a typical packing factor is ~23 m⁻¹.

The geometry also creates many drip points to break the liquid into fine droplets and promote distribution over the packing surface.

3. Manufacturing Process

Injection Molding or Extrusion + Cutting / Molding

The plastic (e.g. PP, PVDF) is melted and molded into the Q-Pack geometry via injection molds or perhaps extrusion + segmentation. High-precision molds are required to ensure dimensional accuracy (e.g. 8.25 cm × 9.5 cm in many designs) and consistent wall thickness.

Cooling / Curing

After molding, parts are cooled under controlled conditions to reduce internal stresses and warpage.

Post-processing / Finishing

Some trimming or removal of runners or gates, inspection of dimensional tolerances, quality check of surfaces (e.g. no burrs, no sharp edges, uniform thickness).

Quality Inspection & Testing

- Dimensional checks

- Weight / density checks

- Visual inspection for defects or warpage

- Possibly mechanical strength tests

- Chemical resistance tests if required

Packaging & Labeling

The Q-Pack elements are often packed in plastic bags, cartons, or bulk jumbo bags (super sacks) for shipment.

Storage / Delivery Logistics

Careful handling to prevent deformation, maintain cleanliness, and avoid UV or mechanical damage before installation.

4. Key Properties & Performance Advantages

| Feature | Typical Value | Benefit / Explanation |

|---|---|---|

| Void fraction / open volume | ≈ 96.3 % (i.e. very high) | Permits high gas throughput with low resistance (low pressure drop) |

| Packing factor (surface area factor) | ~ 23 m⁻¹ | Provides large gas-liquid contact area per unit volume |

| Drip points / droplet generation | High (e.g. ~388,000 dripping points per m³) | Better liquid dispersion, reduced channeling, improved mass transfer |

| Low pressure drop | Q-Pack is designed to have significantly lower ΔP than older packings (e.g. < 3.5″ water column in typical designs) | Lower blower energy, lower operating cost |

| Fouling / plugging resistance | The bar-and-rod geometry and self-cleaning drip points reduce accumulation of scale, biological growth, solids | Lower maintenance, longer uptime |

| Compact footprint | The efficiency allows using smaller tower diameters, smaller packed volume, less overall bulk | Capital cost savings |

| Chemical / thermal resistance | Depends on material (e.g. PVDF offers higher temperature & chemical resistance) | Suitable for more aggressive environments |

| Mechanical strength / stability | Adequate to support distribution grids and liquid loads without deformation | Ensures durability in service |

5. Applications & Use Cases

Plastic Q-Pack tower packing finds use in a wide range of industries and processes, particularly wherever gas–liquid contact and mass transfer are involved. Some typical applications include

1. Wet Scrubbers / Gas Absorbers

Used in air pollution control, flue gas desulfurization, acid gas removal, NOₓ / SO₂ / HCl scrubbing, VOC absorbers. The efficient gas–liquid contact helps removal of pollutants.

2. Air Stripping / Gas Stripping

Used to strip volatile compounds (e.g. VOCs, CO₂) from aqueous streams. Q-Pack offers low pressure drop and good mass transfer.

3. Water & Wastewater Treatment

Pretreatment / filtration: As a filter medium, sometimes combined with sand or dual-media systems.

Biological treatment / biofilm support: The large surface area supports biofilm growth (e.g. in biological aerated filters)

Reclaimed water, tertiary filtration, potable water

4. Desalination & Seawater Treatment

In pre-treatment filters for reverse osmosis or membrane systems, to reduce fouling / suspended solids load.

5. VOC Control / Odor Abatement

Removal of volatile organic compounds from gas streams in chemical plants, paint shops, petrochemical facilities etc.

6. Retrofit Applications

Existing towers with less-efficient packings (e.g. Pall rings, Raschig rings) can sometimes be upgraded to Q-Pack to increase capacity or reduce pressure drop.

7. Cooling / Condensers / Gas Cooling Towers

In certain designs, Q-Pack can also serve in gas cooling / condensation operations, when gas-liquid contact is needed.

6. How Buyers / Users Should Select the Right Q-Pack for Their System

To choose the most suitable Q-Pack for a given application, users should consider the following key parameters and selection criteria:

- Chemical & Corrosion Conditions

- Determine the gas, liquid, and contaminants (acids, bases, halogens, solvent vapors)

- Choose a material (PP, PVDF, CPVC, etc.) compatible with those chemicals

- Check long-term chemical aging resistance

- Operating Temperature

- Ensure the plastic material can withstand the maximum temperature expected in the tower (e.g. PVDF for higher temps)

- Pressure Drop / Gas Flow Rate

- Calculate required gas velocities and allowable ΔP

- Q-Pack is advantageous where low ΔP is critical

- Mass Transfer Requirements

- Required removal efficiency, outlet concentrations

- L/G (liquid/gas) ratios and loading

- Based on transfer coefficient models, one can size packing height

- Tower Geometry / Diameter

- The packing must physically fit the tower cross-section

- For high throughput, Q-Pack allows smaller tower diameters

- Uniform packing support and distribution are needed

- Liquid Loading / Flooding Limits

- Check the flooding capacity at design L/G

- Ensure the packing can operate without flooding under conditions

- Fouling / Particulate Load

- In dirty or particulate-laden streams, evaluate fouling tendency

- Optionally select more open geometry or consider precoating / cleaning schemes

- Mechanical Strength & Support

- Packing must withstand hydraulic pressure, distributor load, shock loads

- Consider reinforced materials (RPP) if needed

- Cost & Lifecycle

- Capital cost of packing vs. operating cost (energy, maintenance)

- Life expectancy under chemical and mechanical conditions

https://chempacking.cn/wp-content/uploads/2024/10/1644393022872159.jpg

7. Zhongci Plastic Q-Pack / Octagonal Q-Pack Tower Packing for Scrubbers

High-Efficiency Mass Transfer, Low Pressure Drop, Fouling-Resistant

Zhongci Environmental Ceramics Materials (www.chempackings.com) proudly offers Octagonal Plastic Q-Pack Tower Packing — a premium random packing media for scrubbers, absorbers, water treatment, VOC control, and gas-liquid contact systems.

Why Choose Zhongci Q-Pack?

- Superior Geometry: Engineered octagonal/bar-and-rod design delivers high voidage (~96.3 %) and abundant drip points for excellent liquid dispersion and enhanced mass transfer.

- Low Energy Costs: Designed to minimize pressure drop, reducing blower power and operational expense.

- Robust & Durable: Manufactured from high-quality thermoplastics (PP, PVDF, CPVC, etc.) with excellent chemical and thermal resistance.

- Anti-Fouling & Low Maintenance: Self-cleaning drip structure resists scale, biological growth, and clogging, reducing downtime.

- Flexible Application: Suitable for scrubbers, absorbers, water filtration, VOC abatement, and retrofit upgrades.

- Tailored Design Support: Our team can assist with sizing, pressure-drop curves, and system integration to reduce risk and speed up commissioning.

Typical Applications

- Flue gas / acid gas scrubbers

- VOC absorption towers

- Air stripping systems

- Water & wastewater filtration / biological treatment

- Seawater desalination pre-treatment

- Retrofit upgrades converting older packing media to Q-Pack

Selecting the Right Q-Pack with Zhongci

- Define your chemical, temperature, gas and liquid conditions

- Choose the appropriate plastic material

- Determine target removal efficiency and gas/liquid loading

- Let our design engineers propose packing height and ΔP curves

- We provide technical datasheets, test cases, and after-sales support

Why Work with Zhongci?

- Strong manufacturing capability and quality control

- Competitive pricing direct from factory

- Comprehensive technical support and design services

- Reliable logistics and global export experience

- We stand by our products — backed by performance guarantees

Contact Us at Zhongci Environmental Ceramics Materials (www.chempackings.com) to request a quote, datasheet, or design support today.