Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

Annular Plastic Teller Rosette Ring for Water Treatment

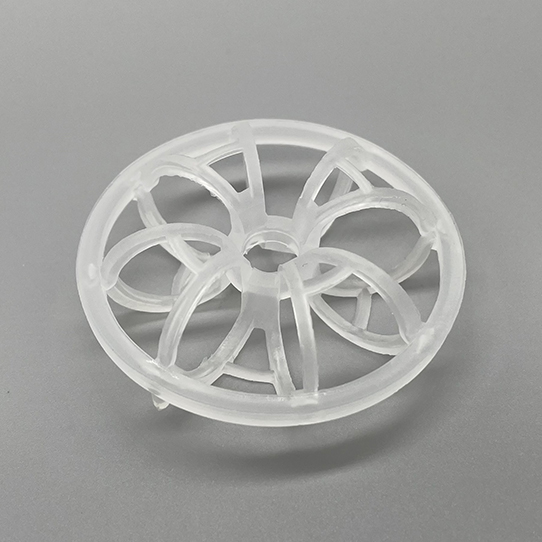

Plastic teller rosette ring is also called plastic teller ring, plastic rosette ring. Plastic teller rosette ring has an annular design. Many small rings are arranged in radial direction inside of its ring-shaped structure. These small plastic rings have many joint points, which can enlarge the gas-liquid contact surface and time. Due to its high void rate and large flux, plastic rosette ring is not easy to plug. It has good resistance to fouling and plugging. Therefore, plastic teller ring performs well in mass transfer applications.

Specifications:

Plastic rosette ring has light weight, low pressure drop, low mass transfer unit height and low cost. It’s applicable working temperature ranges from 60℃ to 150℃. Plastic teller rosette ring is available in different materials, shapes and sizes. It is fit for gas absorption, water treatment and purification. This type tower packing is commonly used in purification towers, cooling towers, washing towers and rectifying columns.

• Material: PE (polyethylene), PP (polypropylene), RPP (reinforced polypropylene), PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride) and PVDF (polyvinylidene fluoride).

• Package: plastic bags

The Technical Parameter of Plastic Teller Rosette Ring | |||||||

Item | Size | Ring Quantity | Surface Area | Voidage | Bulk Number | Bulk Density | Dry Packing Factor |

PTRT-01 | 25 × 9 × (1.5 × 2) | 5 | 269 | 82% | 170000 | 85 | 488 |

PTRT-02 | 47 × 19 × (3 × 3) | 9 | 185 | 88% | 32500 | 58 | 271 |

PTRT-03 | 51 × 19 × (3 × 3) | 9 | 180 | 89% | 25000 | 57 | 255 |

PTRT-04 | 59 × 19 × (3 × 3) | 12 | 127 | 89% | 17500 | 48 | 213 |

PTRT-05 | 73 × 27.5 × (3 × 4) | 12 | 94 | 90% | 8000 | 50 | 180 |

PTRT-06 | 95 × 37 × (3 × 6) | 18 | 98 | 92% | 3900 | 52 | 129 |

PTRT-07 | 145 × 37 × (3 × 6) | 20 | 65 | 95% | 1100 | 46 | 76 |

Features:

• High void rate.

• Low pressure drop.

• Fouling and plugging resistance.

• Good corrosion resistance.

• High mass transfer efficiency.

• Energy saving.

Applications:

• Used in water treatment process.

• Used in absorption, extraction, scrubbing, stripping and heat transfer.

• Applied in purification towers, cooling towers, washing towers and rectifying columns.

• Applied in the packed towers of petroleum industries, chemistry industries, coal gas industries and environmental protection industries.