Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

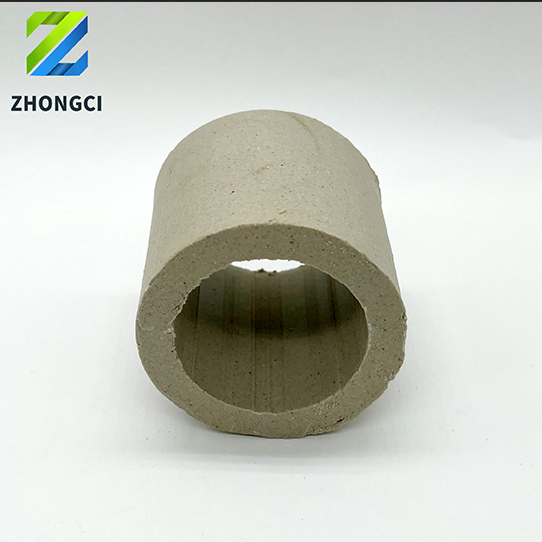

Ceramic Raschig Ring

Ceramic raschig ring is the earliest generation of random packing. The height and diameter of ceramic raschig ring is same and the common specifications are 25 mm to 76 mm.

Ceramic raschig ring has excellent acid resistance and heat resistance performance. It can resist to any inorganic acids, organic acids and organic solvents except for hydrofluoric acid.

The wall thickness of ceramic raschig ring should be thinner under acceptable strength. Though the mass transfer of ceramic raschig ring is low, but it is much cheaper than other random packing, so it is still widely accepted than some industries.

Features & Benefits

·Economical and low price.

·Simple structure.

·Acid and alkali resistance.

·High or low temperature resistance.

Applications

·It is widely used in high or low temperature conditions.

·Ceramic raschig ring is widely used in the drying tower, absorption tower, cooling tower and washing towers in chemical, metallurgy, coal gas, industrial oxygen production industries.

Chemical properties of Ceramic raschig ring | |||

SiO2+ Al2O3 | > 92% | CaO | < 1.0% |

SiO2 | > 76% | MgO | < 0.5% |

Al2O3 | > 17% | K2O + Na2O | < 3.5% |

Fe2O3 | < 1.0% | Other | < 1% |

Physical Properties of Ceramic raschig ring | |||

Water Absorption | < 0.5% | Moh’s Hardness | > 6.5 scale |

Porosity | < 1% | Acid Resistance | > 99.6% |

Specific Gravity | 2.3–2.4 g/cm3 | Alkali Resistance | > 85% |

Max. Operation Temp. | 1200 °C | ||

Common Specifications of Ceramic Raschig Ring | |||||||

Item | Sizes | Thickness | Surface Area | Voidage | Bulk Quantity | Bulk Density | Packing Factor |

CRRS-01 | 6 × 6 | 1.6 | 712 | 62 | 3022935 | 1050 | 5249 |

CRRS-02 | 13 × 13 | 2.4 | 367 | 64 | 377867 | 800 | 1903 |

CRRS-03 | 16 × 16 | 2.5 | 305 | 73 | 192 500 | 800 | 900 |

CRRS-04 | 19 × 19 | 2.8 | 243 | 72 | 109122 | 750 | 837 |

CRRS-05 | 25 × 25 | 3.0 | 190 | 74 | 52000 | 650 | 508 |

CRRS-06 | 38 × 38 | 5.0 | 121 | 73 | 13667 | 650 | 312 |

CRRS-07 | 40 × 40 | 5.0 | 126 | 75 | 12700 | 650 | 350 |