Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

Advantage of DPF

1. Low pressure drop.

2. Low coefficient of thermal expansion.

3. Good thermal shock resistance.

4. High temperature resistance, good resistance to chemical corrosion.

5. High porosity, pore size distribution uniform, high filter specific surface area.

6. Long-term durability performance.

7. High particulate trapping efficiency, suitable for all kinds of regeneration.

Diesel particulate filter is suitable for exhaust gas purification of various kinds of diesel vehicles and ships. We can produce

Cordierite diesel particulate filter and silicon carbide diesel particulate filter.

If you want know more things about the DPF, please contact us directly, I will do my best to service for you.

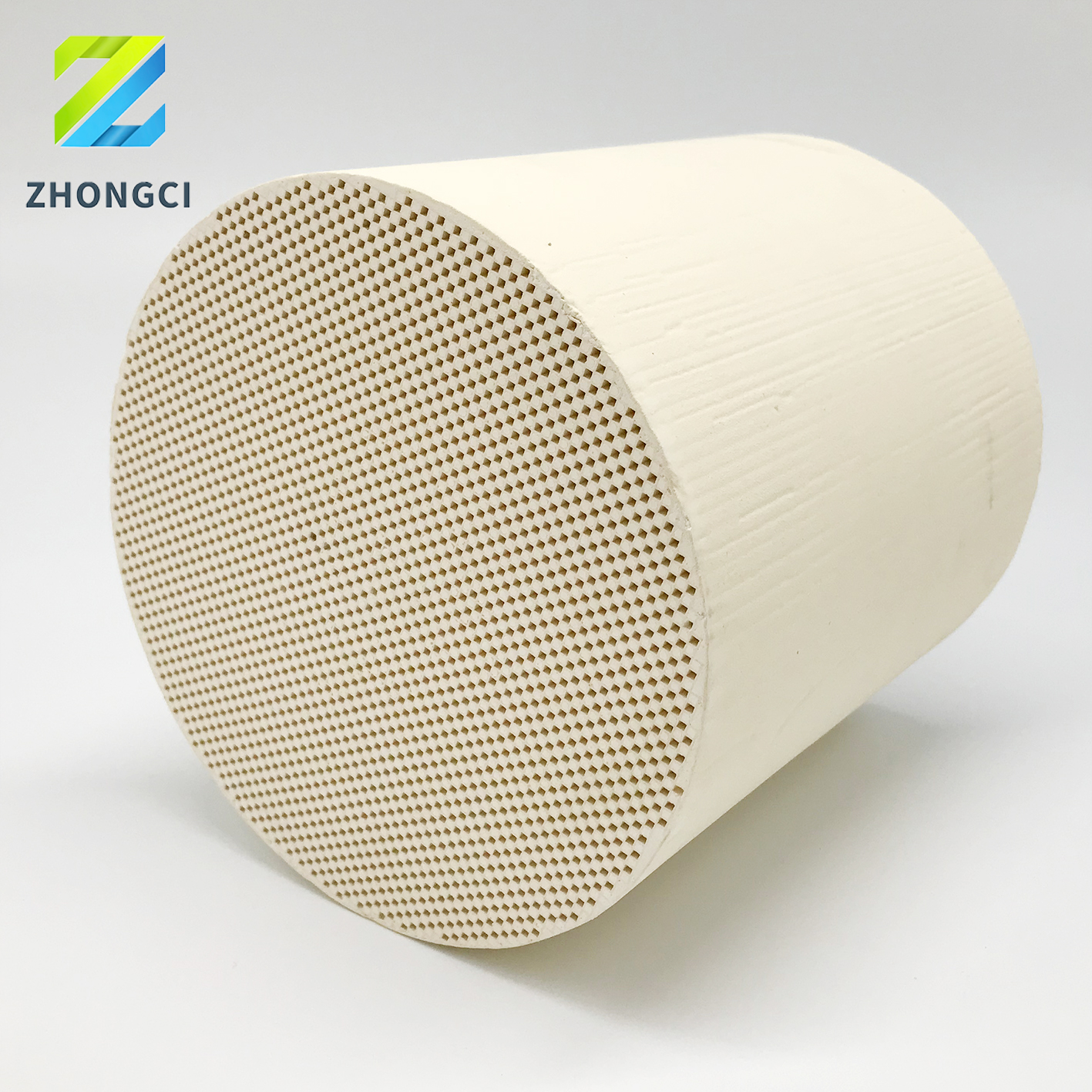

Cordierite Diesel Particulate Filter(DPF)

The most common filter is made of cordierite. Cordierite filters provide excellent filtration efficiency, are relatively

inexpensive (comparison with Sic wall flow filter). The major drawback is that cordierite has a relatively low melting point.

By forcing the exhaust gases through the walls between the channels of the DPF, the particulate matter is deposited on the walls,so reducing the amount of air pollution.

Specification

φ118*152.4 | 100/200 | 1.67 |

φ118*254 | 100/200 | 2.78 |

φ127*152.4 | 100/200 | 1.93 |

φ127*180 | 100/200 | 2.3 |

φ127*254 | 100/200 | 3.22 |

φ144*152.4 | 100/200 | 2.49 |

φ144*203 | 100/200 | 3.31 |

φ144*254 | 100/200 | 4.44 |

φ144*305 | 100/200 | 4.97 |

φ190*152.4 | 100/200 | 4.32 |

φ190*203 | 100/200 | 5.76 |

φ190*305 | 100/200 | 8.65 |

φ240*240 | 100/200 | 10.9 |

φ240*305 | 100/200 | 13.8 |

φ250*305 | 100/200 | 14.97 |

φ267*267 | 100/200 | 14.22 |

φ267*305 | 100/200 | 14.95 |

φ286*305 | 100/200 | 17.07 |

φ286*355 | 100/200 | 19.6 |

φ305*305 | 100/200 | 22.8 |

φ330*381 | 100/200 | 32.59 |

We can OEM any size,you can send you the drawing.

Parameters | Unit | Data | ||

Material: Cordierite | wt% | ≥90 | 94 | |

Coefficient of Thermal Expansion(20-800℃) | cm/cm/℃ | ≤1.8*10 | ≤1.5×10-6 | |

Thermal Stability (20-650℃) | times | ≥1 | 3 | |

Soften Temperature | ℃ | ≥1420 | 1440 | |

Compression Strength | Lengthways | MPa | 16 | 16.9 |

Horizontal | MPa | 5 | 6.2 | |

Specific Weight | Kg/L | 0.45-0.55 | 0.45-0.5 | |

Porosity | % | 40-45 | 41 | |

Water-absorbing rate | % | 23-25 | 23.8 | |