Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

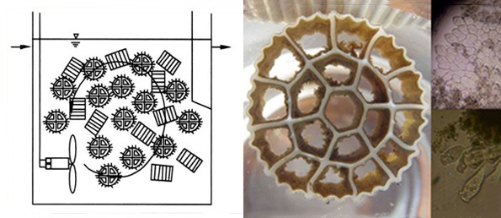

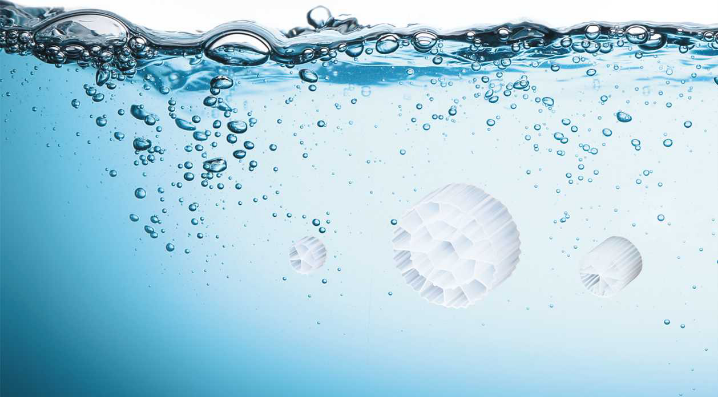

MBBR Filter Media

MBBR Filter Media Product Introduction

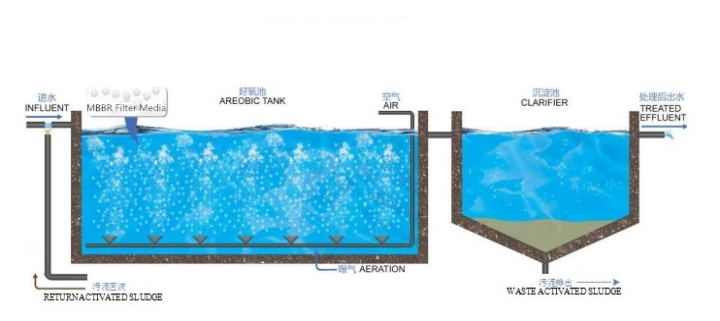

The moving bed biofilm reactor (MBBR) is an efficient biofilm technology, which combines the advantages of traditional fluidized bed.

The MBBR process adds a certain amount of suspended filler (biofilm carrier) to the reactor, and in the protected area of the filler, different microorganisms (from bacteria to ciliates to rotifers) concentrate on the biofilm. Some anaerobic or aerobic bacteria are grown inside the carrier, while aerobic bacteria are grown outside. Each carrier is a micro-reactor, which ensures extensive and frequent contact between waste water and biofilms on the carrier, either through blast aeration in the aerobic treatment system or stirring in the anaerobic treatment system. While improving the mass transfer efficiency of the system, the renewal of biofilm microorganisms should be strengthened to maintain and improve the activity of biofilm. The suspended carrier and the original activated sludge form a more complex complex ecosystem and the biofilm attached to the carrier greatly increases the active biomass in the reactor. Under the joint action of suspended activated sludge and biofilm on the surface of suspended carrier, the impact load resistance capacity of the system is greatly improved, so as to improve the efficiency of sewage treatment and stabilize the effluent quality.

Technical advantagies of Our MBBR Filter Media

1.High hydrophilicity and excellent adhesion to surfaces

2.High bio-activity and bio-film short time

3.High impact resistance and stable operation

4.Less residual sludge

5.High volume load, high filling rate and less land occupation

6.Cost-effective, easy to operate and maintain

7.Rebuild-free, easy to upgrade or expand

8.Long service life: MBBR life more than 15 years

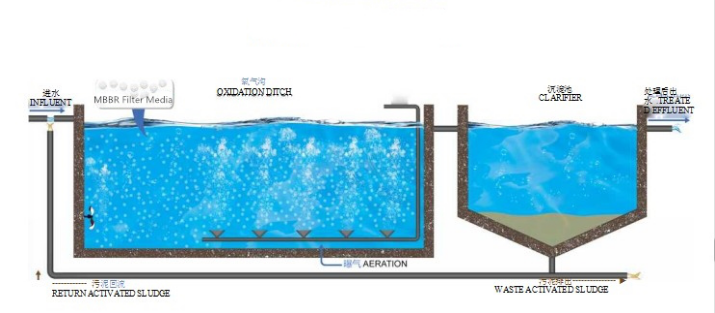

MBBR Filter Media Working Principle

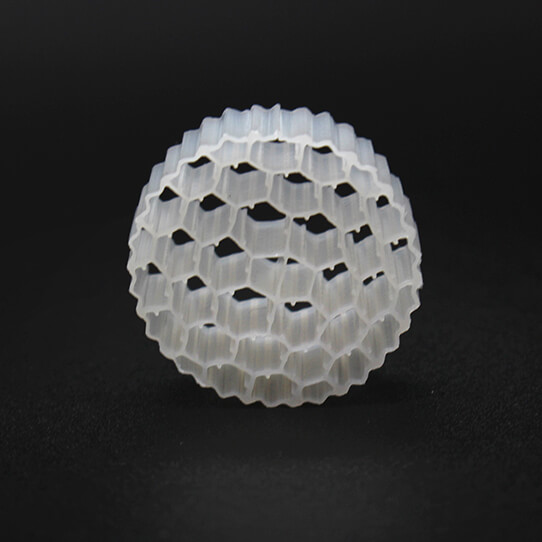

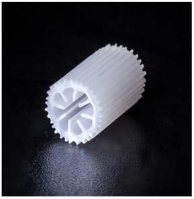

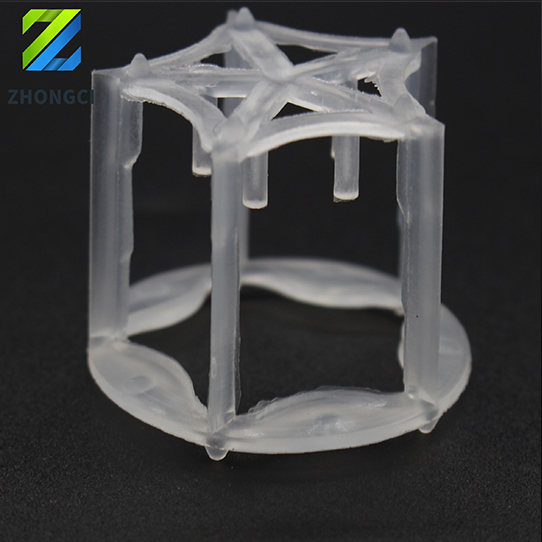

MBBR Filter Media Core Technology

1.Special design of surface, stronger bio-film growth capacity;

1.Special design of surface, stronger bio-film growth capacity;

2.Large specific surface area, high voidage, the more periphyton biomass;

3.Unique design of structure and shape according to hydromechanics, strong three-dimensional flow dynamics in the water;

4.Adding hydrophilic groups and other trace elements, the biofilm formation time only 3-15 days;

5.Excellent impact strength, strong gas shear capacity;

6.Without any holder, easy to cure, save energy and space.

MBBR Filter Media Product Description

Model: PE01 | Model: PE02 | ||

| Spec.: Φ12*9 mm Surface area : >800㎡/m³ Density : 0. 94-0. 97 g/m³ Packing numbers : >630000 pcs/m³ Dosing ratio : 15%-70% Life span : >15 years Nitrfication efficiency : 400-1200 gNH4-N/m³.d Material : 100% Virgin HDPE |

| Spec.: Φ11*7 mm Surface area : >900㎡/m³ Density : 0. 94-0. 97 g/m³ Packing numbers : >830000 pcs/m³ Dosing ratio : 15%-68% Life span : >15 years Nitrfication efficiency : 400-1200 gNH4-N/m³.d Material : 100% Virgin HDPE |

Model: PE03 | Model: PE04 | ||

| Spec.: Φ10*7 mm Surface area : >1000㎡/m³ Density : 0. 94-0. 97 g/m³ Packing numbers : >850000 pcs/m³ Dosing ratio : 15%-70% Life span : >15 years Nitrfication efficiency : 400-1200 gNH4-N/m³.d Material : 100% Virgin HDPE |

| Spec.: Φ16*10 mm Surface area : >800㎡/m³ Density : 0. 94-0. 97 g/m³ Packing numbers : >260000 pcs/m³ Dosing ratio : 15%-67% Life span : >15 years Nitrfication efficiency : 400-1200 gNH4-N/m³.d Material : 100% Virgin HDPE |

Model: PE05 | Model: PE06 | ||

| Spec.: Φ25*10 mm Surface area : >500㎡/m³ Density : 0. 94-0. 97 g/m³ Packing numbers : >97000 pcs/m³ Dosing ratio : 15%-65% Life span : >15 years Nitrfication efficiency : 400-1200 gNH4-N/m³.d Material : 100% Virgin HDPE |

| Spec.: Φ25*12 mm Surface area : >600㎡/m³ Density : 0. 94-0. 97 g/m³ Packing numbers : >97000 pcs/m³ Dosing ratio : 15%-65% Life span : >15 years Nitrfication efficiency : 400-1200 gNH4-N/m³.d Material : 100% Virgin HDPE |

Model: PE08 | Model: PE09 | ||

| Spec.: Φ5*10 mm Surface area : >3500㎡/m³ Density : 1.02-1.05g/m³ Packing numbers : >200000 pcs/m³ Dosing ratio : 15%-70% Life span : >15 years Nitrfication efficiency : 500-1400 gNH4-N/m³.d Material : 100% Virgin HDPE |

| Spec.: Φ15*15 mm Surface area : >900㎡/m³ Density : 0.94-0.97g/m³ Packing numbers : >230000 pcs/m³ Dosing ratio : 15%-65% Life span : >15 years Nitrfication efficiency : 500-1400 gNH4-N/m³.d Material : 100% Virgin HDPE |

Model: PE38 | |||

| Spec.: Φ25*10 mm Surface area : >800㎡/m³ Density : 0.94-0.97g/m³ Packing numbers : >210000 pcs/m³ Dosing ratio : 15%-70% Life span : >15 years Nitrfication efficiency : 500-1200 gNH4-N/m³.d Material : 100% Virgin HDPE | ||

WE OFFER OEM SERVICE

MBBR Filter Media Technology

1.MBBR-SBR SLUDGE PROCESS

2.ANAEROBIC-ANOXIC-OXIC PROCESS

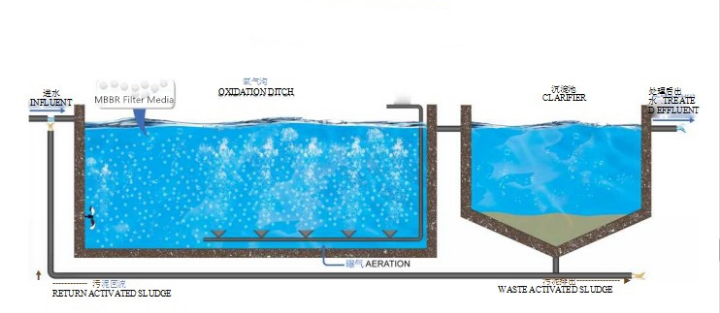

3.OXIDATION DITCH-MBBR PROCESS

Our MBBR filter media can be used in any kind of Pond, it’s no need special pond, and it can used the same pond as before if we change the system to MBBR treatment system, what’s the most important thing is MBBR can be full use of pond volume.

Accelerate the reaction rate significantly, compared with the activated sludge process, reaction efficiency 5 ~10 times.

Simultaneous nitrification and denitrification process,it can be a good denitrification and phosphorus removal

It is no need bracket, just put MBBR filter media directly in.

Our MBBR filter media packing free flow and cutting air bubbles in water, increase dissolved oxygen in water, save energy consumption.

MBBR Filter Media Using Advantages

1.Rapid carrier biofilm formation mechanism:

Specific trace element vector into and special surface treatment process, the microorganisms in water on the carrier attached rapidly and rapidpropagation of growth, biofilm formation in different water conditions, and biofilm schedule differences, generally, the hang film need 3-15 days.

2.Super decarburization, ammonia nitrogen removal capacity:

Carrier provide a safe and comfortable environment for microbial breeding, Biological variety, because of no sludge age limit, nitrifying bacteria have also been large-scale breeding, microbial population huge is dissolved organic.

3.Excellent resistance to shock load performance:

Efficient processing capacity, its ability to remove organic matter 2-5 times higher than that of other traditional methods, high concentrations of biomass and diversity of biological fungus, strong resistance to impact load capacity.

4.Application of flexible and diverse way:

Different stages can be applied to the good nitrogen, anaerobic, anoxic process, only need to handle effect by adding ZhongTai MBBR filter media can easily obtain satisfactory result.

5.Simple operation and maintenance:

Without support, put ZhongTai MBBR filter media in the pool directly, and it can save the return sludge, avoiding sludge bulking, come-up and loss, convenient to operate and maintain.

6.Long service life:

Through a special process modification, ZhongTai MBBR filter media have a good resistance, UV resistance, strong toughness, not easy to aging and embrittlement, and it has a long service life.

7.Deoxidation and phosphorus removal effect is good:

Due to the biological film have a strong digestive ability, water ammonia nitrogen can be completely transformed into nitrate and ammonia, the denitrification can give full play to the maximum, denitrification more thoroughly. Meanwhile biofilm huge phosphorus phosphate material flora water thoroughly absorbed, and through the biological film off into the sedimentation tank and eventually to the sludge discharged system, the phosphorus removal effect more obvious.

MBBR Filter Media Application Industry

Municipal, Power, Pharmaceutical, Chemical, Electroplating, Metallurgy, Machinery, Papermaking, Printing and Dyeing, Medicine, Food processing, Aquaculture, with the continuous improvement and the deepening use of our products, ZhongTai MBBR filter media will be used more and more widely.

ZhongTai MBBR filter media can be used in project title, the amount of upgrading sewage treatment plant, New sewage treatment project of MBBR and BAF process, Biochemical treatment of reclaimed water, River nitrogen, phosphorus removal, Aquaculture in removal of ammonia nitrogen, water purification, Biological filler biological deodorization tower.

MBBR Filter Media Engineering Projects

Application I : Sewage Treatment – Activated Sludge Process

Principal Technology

Inflow → Primary Clarifier → MBBR Tank → Secondary Clarifier → Effluent

Application II:Sewage Treatment – Anaerobic-Anoxic-Oxic

Principal Technology

Inflow → Anaerobic MBBR Tank → Anoxic MBBR Tank →Oxic MBBR Tank →Clarifier → Effluent

Application III:Sewage Treatment – Oxidation Ditch Process

Principal Technology

Inflow → Anaerobic MBBR Tank → Oxidation Ditch+MBBR Tank → Clarifier → Effluent

Application IV:Fishery Water Treatment Process

Principal Technology

Inflow → Darkroom → MBBR Tank → Clarifier → UV Disinfection Tank → Effluent

Application V:Fishery Water Treatment Process

Principal Technology

Inflow → Darkroom → Anaerobic MBBR Tank → Oxic MBBR Tank → Clarifier → UV Disinfection Tank →Effluent

Application VI:Industrial Water Reuse Technology

Principal Technology

Inflow → Dosing Coagulation → Primary Clarifier → MBBR Tank → Secondary Clarifier → Effluent

Application VII:MBBR Integrated Equipment

Principal Technology

Inflow → The Integration of MBBR Biochemical Tank (Anaerobic Tank Oxic Tank) → Effluent