Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

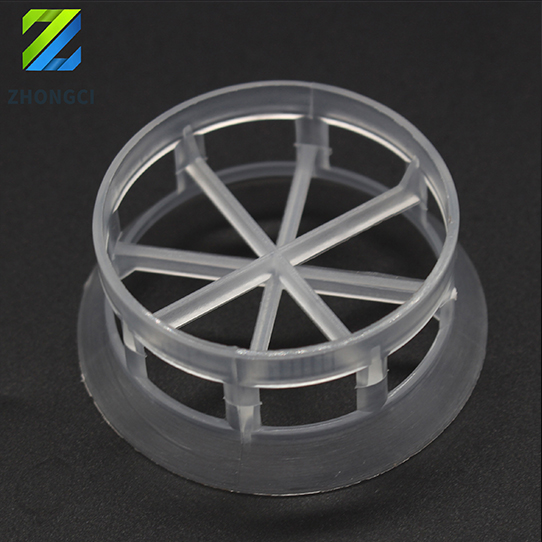

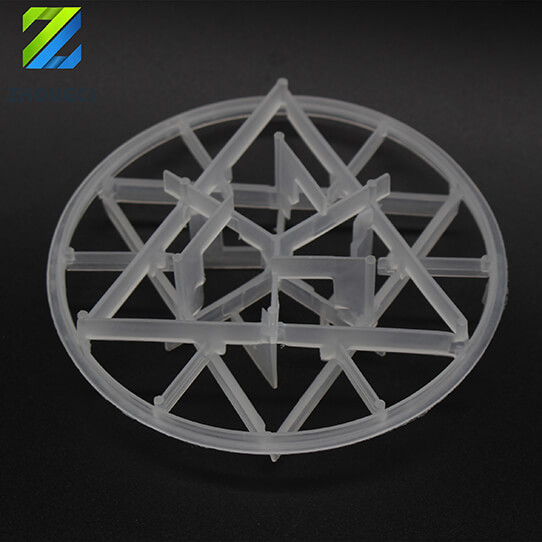

Plastic Cascade Mini Ring with good Fouling Resistance

Plastic cascade mini ring is a type of high performance plastic random packing. Its vertical axis orientation allows more fluids to pass through the cylinder. Solids are easily washed away by the fluids. Therefore, plastic cascade mini ring has good fouling resistance. It is characterized by low aspect ratio, good corrosion resistance and excellent separation effect. Plastic cascade mini ring has larger capacity and higher efficiency than plastic pall ring.

Specifications Plastic Cascade Mini Ring with good Fouling Resistance:

This type of tower packing can be made from various corrosion resistant materials, such as polypropylene, polyethylene and polyvinyl chloride. Compared with metal cascade mini ring, it has better corrosion resistance and lower costs. Plastic cascade mini ring is fit for the desulfurization, decarbonization and crude oil separation system. It is widely used in absorption, extraction, scrubbing, stripping and heat transfer applications.

Material of Plastic Cascade Mini Ring with good Fouling Resistance:

Plastic tower packing can be made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinyiidene fluoride (PVDF) and Polytetrafluoroethylene (PTFE). The temperature in media ranges from 60 Degree C to 280 Degree C

Plastic Tower Packings: plastic pall ring, plastic saddle, plastic super saddle, plastic cascade ring, plastic conjugate ring, plastic teller rosette ring, plastic hi-flow ring, plastic snowflake ring, plastic VSP ring, plastic tri-pack, etc.

Physical & chemical properties of plastic Random Packing:

| Performance / Material | PE | PP | RPP | PVC | CPVC | PVDF |

| Density (g/cm3) | 0.94-0.96 | 0.89-0.91 | 0.93-0.94 | 1.32-1.44 | 1.50-1.54 | 1.75-1.78 |

| Operation Temp.(oC) | 90 | >100 | >120 | >60 | >90 | >150 |

| Chemical corrosion resistance | Good | Good | Good | Good | Good | Good |

| Compression Strength(Mpa) | >6.0 | >6.5 | >7.0 | >6.0 | >8.0 | >10.0 |

● Lifespan: more than 3 years.

● Package: plastic bags, cartons.

The Technical Parameter of Plastic Cascade Mini Ring

Item | Size | Surface Area | Voidage | Bulk Number | Bulk Density | Dry Packing Factor |

PCMT-01 | 16 × 8.9 × 1 | 370 | 85% | 299136 | 135.6 | 602.6 |

PCMT-02 | 25 × 12.5 × 1.2 | 228 | 90% | 81500 | 65 | 312.8 |

PCMT-03 | 38 × 19 × 1.2 | 132.5 | 91% | 27200 | 54 | 175.8 |

PCMT-04 | 50 × 25 × 1.5 | 114.2 | 92.7% | 10740 | 43 | 143.1 |

PCMT-05 | 76 × 37 × 2.6 | 90 | 92.9% | 3420 | 44 | 112.3 |

Features:

·Large capacity.

·Fouling resistance.

·Low pressure drop.

·High mechanical strength.

·Strong corrosion resistance.

Applications:

·Suitable for methanol and organic acids separation.

·Applied in desulfurization and decarbonization system.

·Applied in absorption, extraction, scrubbing, stripping and heat transfer.

·Used in gas dehydration, methane and carbon dioxide removal, etc.

·Applied in carbon dioxide degassing towers, ozone exposure reaction towers, vacuum distillation towers and other reaction towers.