Exhibition

Are Cheap Adsorbents Really New? How to Identify Regenerated?

Learn how to spot the difference between genuine and regenerated silica gel, molecular sieves, and …

99% don’t know! How to choose molecular sieve?

What Are Molecular Sieves? Molecular sieves are microporous, crystalline aluminosilicates (zeolites) with uniform pore sizes. …

More than 50% of people don’t know! How to replace silicone wisely?

What Happens to Silica Gel After Absorbing Moisture? Silica gel is a porous form of …

99% of people don’t know! How to choose an adsorbent?

Learn How to Choose the Right Adsorbent for Your Industrial Needs Adsorbents play a vital …

99% people don’t know! How to choose a bacteria house?

When it comes to keeping koi fish happy and thriving, clean water is key. While …

How to Choose the Right Honeycomb Ceramics?

And Where to Buy Them Honeycomb ceramics are special blocks made from ceramic materials. These …

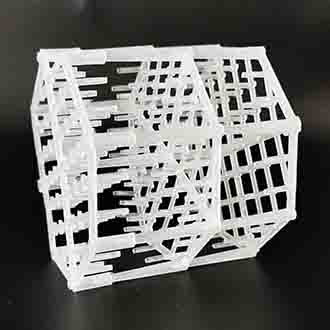

Plastic Hiflow ring

Plastic Hiflow ring is a 3rd generation high performance tower packing which provides an optimal design of high mechanical stability, void fraction and superior mass transfer performance. The grid structure guarantees its opening pore ratio exceed 50% and bed void fraction is higher than same size’s pall ring. In addition, large fluid flux guarantee its pressure drop per square meter lower 45% than pall ring. Vertical bar staggered distribution and reinforced horizonal stripe largely improve its rigidity and strength. It has features such as high free volume, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on.

Specifications of Plastic Hiflow ring:

Plastic tower packing can be made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinyiidene fluoride (PVDF) and Polytetrafluoroethylene (PTFE). The temperature in media ranges from 60 Degree C to 280 Degree C

Plastic Tower Packings: plastic pall ring, plastic saddle, plastic super saddle, plastic cascade ring, plastic conjugate ring, plastic teller rosette ring, plastic hi-flow ring, plastic snowflake ring, plastic VSP ring, plastic tri-pack, etc.

Physical & chemical properties of plastic Random Packing:

| Performance / Material | PE | PP | RPP | PVC | CPVC | PVDF |

| Density (g/cm3) | 0.94-0.96 | 0.89-0.91 | 0.93-0.94 | 1.32-1.44 | 1.50-1.54 | 1.75-1.78 |

| Operation Temp.(oC) | 90 | >100 | >120 | >60 | >90 | >150 |

| Chemical corrosion resistance | Good | Good | Good | Good | Good | Good |

| Compression Strength(Mpa) | >6.0 | >6.5 | >7.0 | >6.0 | >8.0 | >10.0 |

● Lifespan: more than 3 years.

● Package: plastic bags, cartons.

The Technical Parameter of Plastic Hiflow ring

Item | Size | Surface Area | Voidage | Bulk Number | Bulk Density | Dry Packing Factor |

PPRT-01 | 16 × 16 × 1 | 188 | 91% | 170000 | 85 | 275 |

PPRT-02 | 25 × 25 × 1.2 | 175 | 90% | 53500 | 69 | 239 |

PPRT-03 | 38 × 38 × 1.4 | 115 | 89% | 15800 | 69 | 220 |

PPRT-04 | 50 × 50 × 1.5 | 93 | 90% | 6500 | 52 | 127 |

PPRT-05 | 76 × 76 × 2.6 | 73.2 | 92% | 1927 | 48 | 94 |

PPRT-06 | 100 × 100 × 3 | 52.8 | 94% | 1000 | 48 | 82 |

Features:

·Good heat resistance.

·Large internal surface area.

·Effective mass transfer velocity.

·Good chemical resistance.

·High operating flexibility.

·Cost effective.

Applications:

·Applied in various mass transfer towers for stripping, scrubbing and absorption.

·Used in the industries of chemical, gas, petroleum, chlor-alkali and environmental protection.

·Used in carbon dioxide degassing towers, ozone exposure reaction towers, vacuum distillation towers and other reaction towers.