Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

Plastic lamella clarifiers ,Tube settlers

Mainly used in waste water treatment such as all different clarifiers and removing sand. it was regard as a universal water treatment equipment in Water supply and drainage engineering

Descriptions:

Tube settlers, also called lamella clarifiers, are used to remove solids in the waste water treatment.

tube settlers are single plastic profiles combined to tubes. This design multiplies the sedimentation area up to 15 times per square meter surface area and helps to improve sedimentation in water and waste water treatment plants.

Different executions support a better process and cost reduction of the plant.

Advantages of tube settlers (lamella clarifiers)

• Process efficiency

From multiplication of the sedimentation area, chevron equidistant channel shape and adaptation of the settling area spacing and slope

• Flexible dimensions

It can be adapted to all kinds of shapes, inclinations, round settlers and allows cut outs.

• Easy handling

Simple on site assembly method grants low cost, safe delivery to any place in the world.

• Sophisticated support system

With stainless steel and specially shaped glass fibre reinforced plastic beams minimizing turbulence and sludge deposit.

• Strong and high quality material

• We provides high stability of the modules for easy maintenance – PP material approved for high standards of potable water applications

Applications:

Design and build new clarifiers and settling tanks equipped with tube settlers

• Retrofit existing clarifiers and sedimentation basins with tube modules to increase settling capacity and increase throughput

• Provide replacement tube modules for existing installations

Our Environmental designs and builds liquid cleaning and recycling equipment including:

• Circular Clarifiers

• Parallel Plate Settlers

• Tube Settlers

• Horizontal and Vertical Clarifiers

• Air Strippers

• API Separators

• Oil Recovery Units

• Complete Engineered Systems

Technical Data:

Material | D(mm) | T(mm) | Surface area m2/m3 | Porosity (m3/m3) | weight kg/m3 |

PP(non-toxic) | d25 | 0.5 | 236.0987 | 0.9487 | 42 |

d30 | 0.5 | 169.4159 | 0.9570 | 39 | |

d40 | 0.5 | 148.4537 | 0.39675 | 37 | |

d50 | 0.5 | 119.0055 | 0.9739 | 28 | |

d60 | 0.5 | 99.3071 | 0.9781 | 23 | |

PVC(Food grade) | d25 | 0.5 | 236.0987 | 0.9487 | 80 |

d30 | 0.5 | 169.4159 | 0.9570 | 64 | |

d40 | 0.5 | 148.4537 | 0.9675 | 48 | |

d50 | 0.5 | 11.0055 | 0.9739 | 40 | |

d60 | 0.5 | 99.3071 | 0.6781 | 33 |

1. When the inclined tube is 1 meter long, the Surface load is 5-8 tons/m2*H When the design.The V0 control is within the range of 2.5-3.0mm/s, and the water quality is the best.

2. When using the honeycomb inclined tube at the inlet and the pipe length 2.0 ~ 3.0m, it can be safely operated in the high turbidity of the Clay sand content of 50-100kg/m3.

3.The processing power of the inclined tube sedimentation tank is 3-5 times that of the horizontal sedimentation tank, and 2-3 times that of the clarifying tank and the pulse cl

Picture:

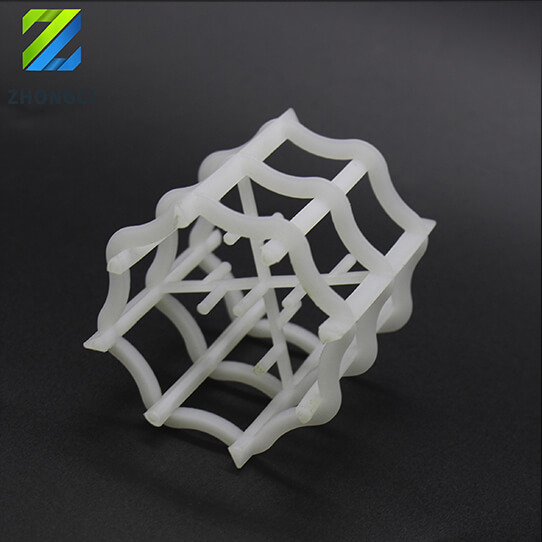

1.Lamella:

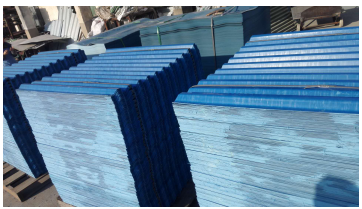

2.Assembling