Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

Plastic Pall Ring with High Mass Transfer Velocity

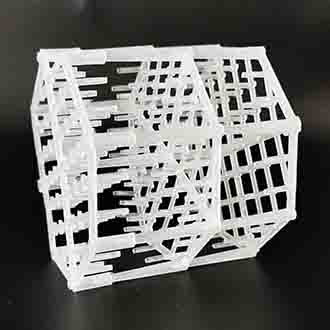

Plastic pall ring is also called plastic pall ring packing. It is a type of random packing, which modifies directly at the shortcomings of raschig ring. This type pall ring makes some structural improvements on the basis of raschig ring. It adds many small rectangular windows on its wall. The blades of these small rectangular windows join together in the center of the pall ring. The openings on plastic pall ring’s lateral wall fully utilize its internal surface area and greatly increase the gas-liquid agitation. Therefore, plastic pall ring has better gas-liquid distribution performance than plastic raschig ring.

Specifications of Plastic Pall Ring:

Plastic pall ring is characterized by high gas velocity, small resistance and large production capacity. It performs well in stripping and scrubbing. This kind pall ring packing has good chemical resistance, it is suitable for various industries, such as chlor-alkali industry, gas industry and chemical industry.

It is widely used in carbon dioxide degassing towers, ozone exposure reaction towers, vacuum distillation towers and other reaction towers.

● Material: PE (polyethylene), PP (polypropylene), RPP (reinforced polypropylene), PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride) and PVDF (polyvinylidene fluoride).

● Lifespan: more than 3 years.

● Package: plastic bags, cartons.

The Technical Parameter of Plastic Pall Ring

Item | Size | Surface Area | Voidage | Bulk Number | Bulk Density | Dry Packing Factor |

ZC-01 | 16 × 16 × 1 | 188 | 91% | 170000 | 85 | 275 |

ZC-02 | 25 × 25 × 1.2 | 175 | 90% | 53500 | 69 | 239 |

ZC-03 | 38 × 38 × 1.4 | 115 | 89% | 15800 | 69 | 220 |

ZC-04 | 50 × 50 × 1.5 | 93 | 90% | 6500 | 52 | 127 |

ZC-05 | 76 × 76 × 2.6 | 73.2 | 92% | 1927 | 48 | 94 |

ZC-06 | 100 × 100 × 3 | 52.8 | 94% | 1000 | 48 | 82 |

Features:

● Good heat resistance.

● Large internal surface area.

● Effective mass transfer velocity.

● Good chemical resistance.

● High operating flexibility.

● Cost effective.

Applications:

● Applied in various mass transfer towers for stripping, scrubbing and absorption.

● Used in the industries of chemical, gas, petroleum, chlor-alkali and environmental protection.

● Used in carbon dioxide degassing towers, ozone exposure reaction towers, vacuum distillation towers and other reaction towers.