Exhibition

How to Choose the Right Perforated Ceramic Ball

Perforated cera …

Zirconia Grinding Media: Stronger, Harder, Better

Zirconia cerami …

Octagonal Plastic Q-Pack: The Best Scrubber Tower Packing

“Octagonal Plas …

Anti-Fouling Heilex Ring: The Best Packing for Gas Cooling

Anti-fouling Pl …

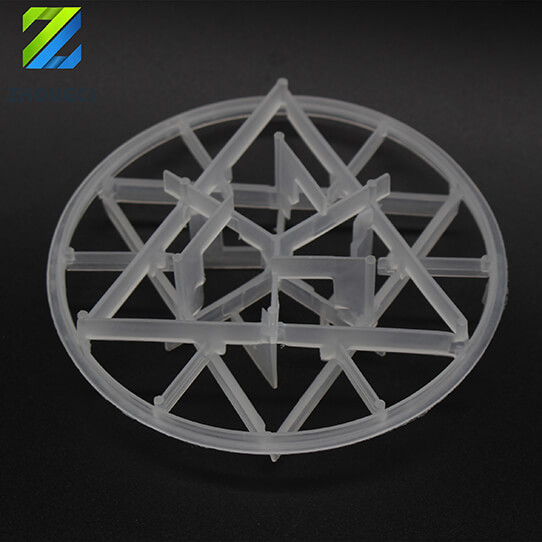

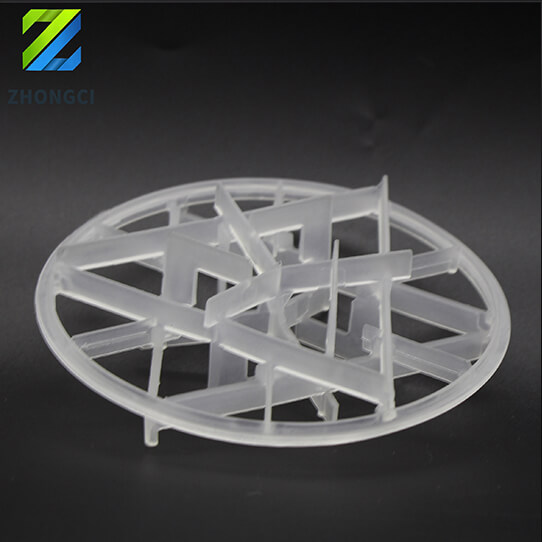

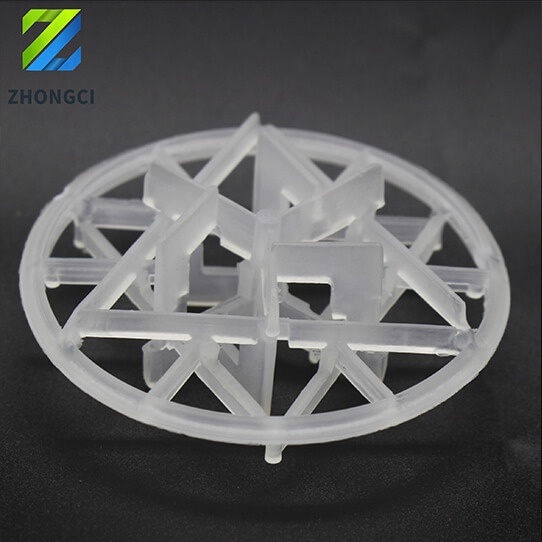

Plastic Snowflake Ring for Scrubbing and Stripping Tower

Plastic snowflake ring is a high-efficiency tower packing. It has a low specific gravity, high flooding point, large porosity, high mass transfer unit height. Besides, this random packing has lower pressure drop, which reduces the back-pressure phenomenon and minimizes the energy consumption of the stripping process. Plastic snowflake ring is very economical. It can be applied in the chlorine and bromine production, air separation and water cooling process

Specifications of Plastic Snowflake Ring:

This tower packing is characterized by good heat resistance, excellent chemical corrosion resistance and high mass transfer efficiency. Plastic snowflake ring is suitable for seawater desulfurization, HCL (hydrogen chloride) absorption and gas-liquid separation. It is widely used in various acid storage tanks and demineralized water tanks of petroleum industry, chemical industry, metallurgy industry and environmental protection industry.

Material of Plastic Snowflake Ring:

Plastic tower packing can be made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinyiidene fluoride (PVDF) and Polytetrafluoroethylene (PTFE). The temperature in media ranges from 60 Degree C to 280 Degree C

Plastic Tower Packings: plastic pall ring, plastic saddle, plastic super saddle, plastic cascade ring, plastic conjugate ring, plastic teller rosette ring, plastic hi-flow ring, plastic snowflake ring, plastic VSP ring, plastic tri-pack, etc.

Physical & chemical properties of plastic Random Packing:

| Performance / Material | PE | PP | RPP | PVC | CPVC | PVDF |

| Density (g/cm3) | 0.94-0.96 | 0.89-0.91 | 0.93-0.94 | 1.32-1.44 | 1.50-1.54 | 1.75-1.78 |

| Operation Temp.(oC) | 90 | >100 | >120 | >60 | >90 | >150 |

| Chemical corrosion resistance | Good | Good | Good | Good | Good | Good |

| Compression Strength(Mpa) | >6.0 | >6.5 | >7.0 | >6.0 | >8.0 | >10.0 |

● Lifespan: more than 3 years.

● Package: plastic bags, cartons.

| type(mm) | Dimension | Surface area | Void rate | Bulk quantity | Bulk density | Dry packing factor m-1 |

| DxHxT mm | m2/m3 | %/m3 | pcs/ m3 | kg/m3 | ||

| 95 | 95x34x1.5 | 138 | 97 | 4900 | 49 | 142 |

Features Plastic Snowflake Ring:

·Large porosity.

·High capacity.

·Low pressure drop.

·High flooding point.

·Uniform gas-liquid distribution.

·Good corrosion resistance.

Applications of Plastic Snowflake Ring:

·Applied in gas and liquid separators.

·Applied in distillation columns, washing towers, cooling towers and stripping towers.

·Used in seawater desulfurization, HCL (hydrogen chloride) absorption and gas-liquid separation.

·Used in chlorine and bromine production factory and air separation plants.