Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

High-Performance Plastic Super Mini Ring for Mass Transfer Efficiency

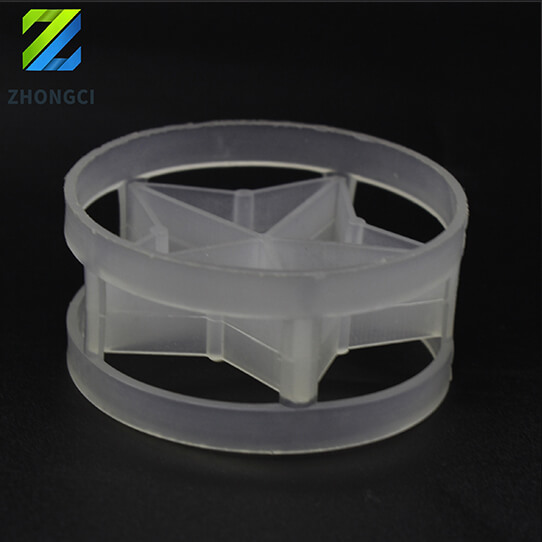

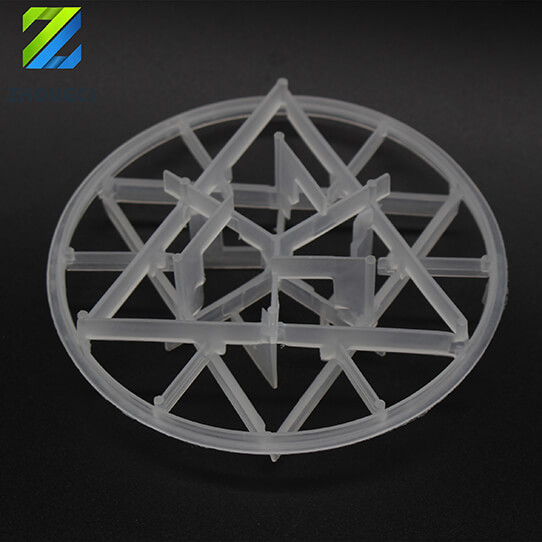

Plastic Super Mini Ring, also called plastic flat ring, is an advanced products of plastic cascade mini ring. In the product design, the plastic super mini ring change the bevel edge of cascade mine ring into flat edge, which can make the structure uniform and improve the bulk density of random packing. Additional, the internal fingers of cascade ring are changed into internal curved rib to increase the packing strength.

High-Performance Plastic Super Mini Ring for Mass Transfer Efficiency

What Is a Plastic Super Mini Ring?

The Plastic Super Mini Ring is an advanced type of random packing used in chemical, petrochemical, and environmental applications. It offers a compact structure with high surface area, low pressure drop, and superior mass transfer efficiency. It’s a modern alternative to traditional packing like Raschig and Pall rings.

Key Features of Plastic Super Mini Rings

High Free Volume

The design offers up to 90% free space, improving gas-liquid contact and reducing energy consumption.Excellent Mass Transfer Efficiency

Its special structure promotes even distribution of liquid and gas, boosting absorption and stripping processes.Low Pressure Drop

The open lattice design minimizes resistance, reducing fan and pump power requirements.Lightweight and Durable

Made from high-quality thermoplastics such as PP, PE, PVC, PVDF, and PTFE. They resist corrosion, high temperatures, and mechanical stress.

Technical Specifications

Material Options: PP, RPP, PVC, CPVC, PVDF, PTFE

Size Range: Common sizes include 15mm, 25mm, 38mm, 50mm

Operating Temperature: Up to 150°C (varies by material)

Bulk Density: Lower than ceramic or metal rings, reducing tower weight

Color: Natural, black, white, or custom upon request

Advantages Over Traditional Packing

Smaller Size, Bigger Impact

Despite being smaller, Super Mini Rings outperform larger packings. They offer more contact points and better dispersion.Faster Start-Up and Shutdown

Their structure allows for quicker reaction time in tower systems.Easy Installation and Replacement

Lightweight material makes handling and refilling simpler.High Chemical Resistance

Ideal for corrosive gas or liquid streams. Suitable for acidic, alkaline, or solvent-rich conditions.

Applications of Plastic Super Mini Rings

Scrubbing Towers

Widely used in gas scrubbers for SO₂, HCl, and other pollutants.Stripping Columns

Effective for ammonia, carbon dioxide, and VOC removal processes.Distillation and Absorption Units

Enhance separation efficiency in chemical and petrochemical plants.Wastewater Treatment Systems

Improve biological contact and aeration in water purification processes.

Specifications:

● Material: PE (polyethylene), PP (polypropylene), RPP (reinforced polypropylene), PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride) and PVDF (polyvinylidene fluoride).

● Lifespan: more than 3 years.

● Package: plastic bags, cartons.

Table 1: Common Specification of Plastic Super Mini Ring | |||||

Item | Size | Surface Area | Voidage | Bulk Number | Dry Packing Factor |

PSMT-01 | 25 × 9 × 1.0 | 160 | 88% | 170000 | 287 |

PSMT-02 | 38 × 13 × 1.2 | 145 | 92% | 460000 | 175 |

PSMT-03 | 50 × 17 × 1.5 | 128 | 93% | 21500 | 140 |

PSMT-04 | 76 × 26 × 2.5 | 116 | 93% | 6500 | 112 |

Features:

● Good heat resistance.

● Large internal surface area.

● Effective mass transfer velocity.

● Good chemical resistance.

● High operating flexibility.

● Cost effective.

Applications:

● Applied in various mass transfer towers for stripping, scrubbing and absorption.

● Used in the industries of chemical, gas, petroleum, chlor-alkali and environmental protection.

● Used in carbon dioxide degassing towers, ozone exposure reaction towers, vacuum distillation towers and other reaction towers.