Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

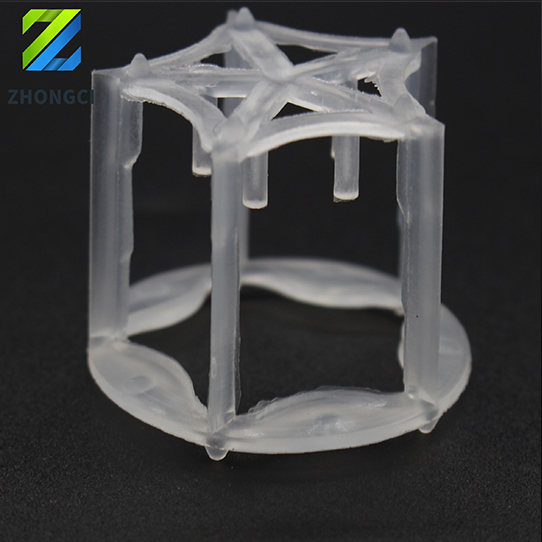

Plastic Tri-Pack

Features of plastic tri-pack

• High mass transfer efficiency.

• Evenly gas and liquid distribution.

• High surface area.

• Extremely low pressure drop.

• Temperature and chemical resistance.

360° shows of plastic tri-pack for comprehensive understanding.

Plastic tri-pack is a type of random tower packing, which has hollow, spherical structure. Plastic tri-pack has a symmetrical geometry, which is made from a unique network of ribs, struts and drip rods. It is made of injection molded plastic, including PP, PE, PVC, PVDF and other materials. The most widely used diameter of plastic tri-pack is 1″, 1-1/4″, 3″ and 3-1/2″.

Available materials

Polypropylene (PP).

Polyethylene (PE).

Polyvinyl chloride (PVC).

Chlorinate polyvinyl chloride (CPVC).

Polyvinylidene Fluoride (PVDF).

Reinforced Polypropylene (RPP).

Sectional view of plastic tri-pack.

Side view of plastic tri-pack.

Plastic tri-pack has a hollow spherical structure with several ribs and struts.

Plastic tri-pack can be customized into any size according to customers’ requirements.

Item | Size | Surface Area | Voidage | Bulk Number | Bulk Density | Dry Packing Factor |

PTPR-01 | 25 | 85 | 90% | 77000 | 81 | 28 |

PTPR-02 | 32 | 70 | 92% | 25000 | 70 | 25 |

PTPR-03 | 50 | 48 | 93% | 10500 | 62 | 16 |

PTPR-04 | 95 | 38 | 95% | 1800 | 45 | 12 |

Table 2: Physical & Chemical Properties of Different Materials of Plastic Tri-Pack | ||||

Material/Performance | Density | Operation Temperature | Chemical Corrosion Resistance | Compression Strength |

PE | 0.98 | 90 | good | >6.0 |

PP | 0.96 | >100 | good | >6.0 |

RPP | 1.2 | >120 | good | >6.0 |

PVC | 1.7 | >60 | good | >6.0 |

CPVC | 1.8 | >90 | good | >6.0 |

PVDF | 1.8 | >150 | good | >6.0 |

Applications of plastic tri-pack

• Gas absorption and purification.

• Gas & liquid separation.

• Liquid extraction.

• Water treatment.

• Biological filtration.