Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

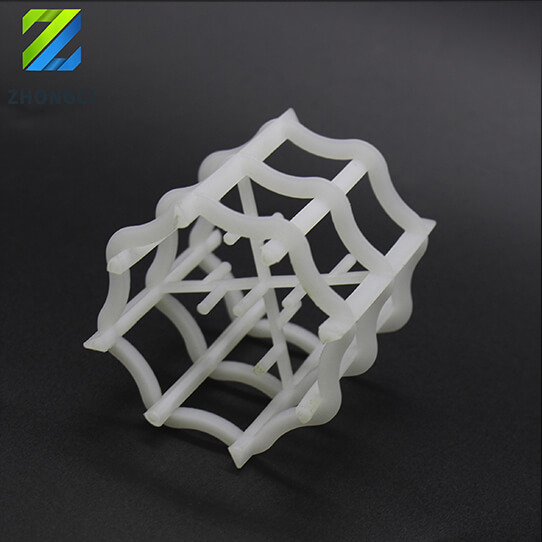

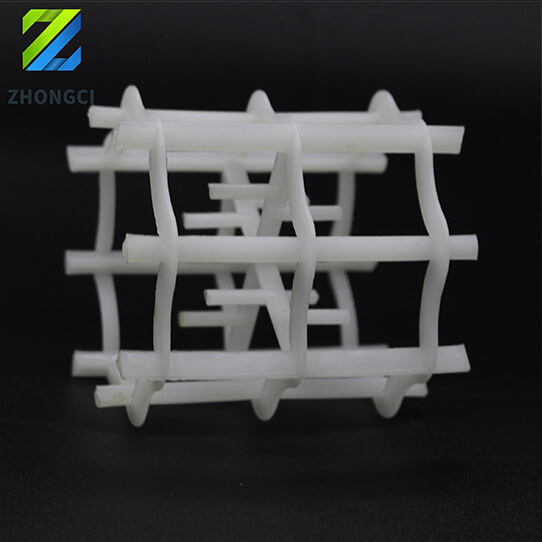

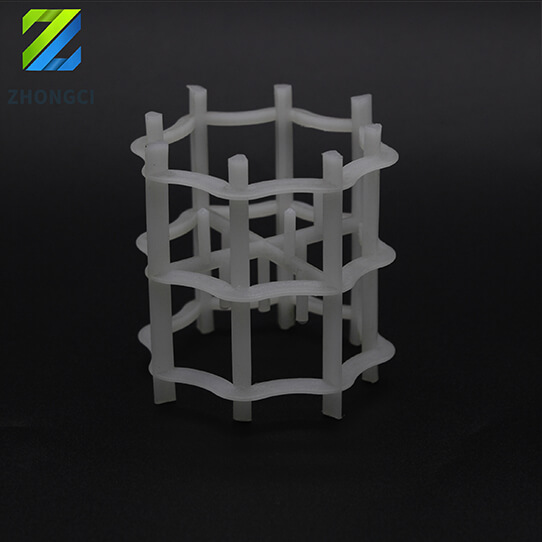

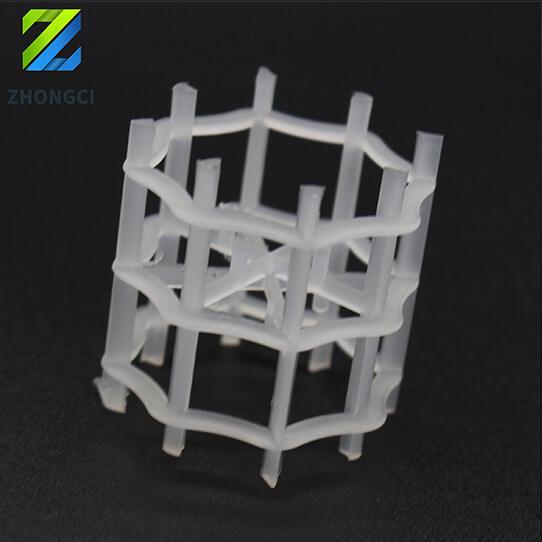

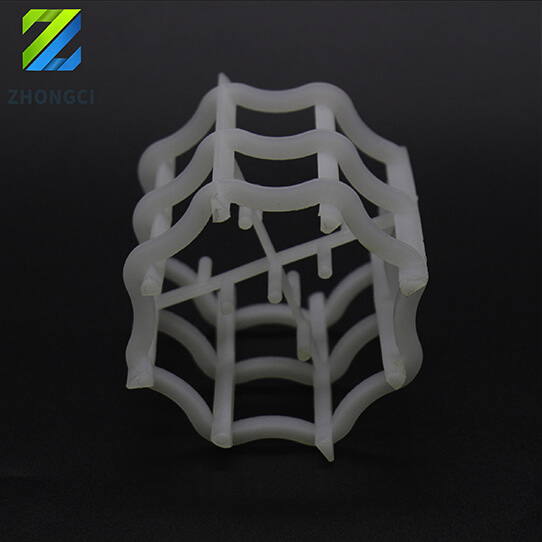

Plastic VSP Ring for tower filter

Description:Plastic VSP Ring for tower filter

HS code:3926909090

Packing:Woven bag

Material:PP PVC PE PVDF CPVC.etc

Plastic VSP Ring for Tower Filter – High-Efficiency Packing Solution

Description of Plastic VSP Ring for Tower Filter:

The Plastic VSP Ring is a high-performance random packing designed for tower filters, offering exceptional mass transfer efficiency with a high void ratio (93–97%), low pressure drop, and uniform gas-liquid distribution. Its lightweight design (specific gravity: 30–60 kg/m³) and high flooding point make it ideal for demanding industrial applications.

Key Advantages:

- ✔ Superior Mass Transfer: Optimized surface area (40–185 m²/m³) ensures efficient contact between gas and liquid phases.

- ✔ Chemical Resistance: Compatible with acids, alkalis, and solvents, thanks to material options like PP, PVC, CPVC, and PVDF.

- ✔ Long Lifespan: Over 3 years of service life, even in corrosive environments.

- ✔ Wide Temperature Range: Withstands temperatures up to 150°C.

Applications of Plastic VSP Ring for Tower Filter

Widely used in:

- Petrochemical (distillation, absorption)

- Alkali Chloride (chlor-alkali processing)

- Gas Processing (scrubbing, CO₂ removal)

- Environmental Protection (waste gas treatment, VOC removal)

Technical Specifications

Materials Available:

- PE (Polyethylene), PP (Polypropylene), RPP (Reinforced PP)

- PVC, CPVC, PVDF (for aggressive chemicals/high temps)

Physical Properties:

| Size (inch/mm) | Surface Area (m²/m³) | Void Ratio (%) | Packing Number (pcs/m³) | Density (kg/m³) |

|---|---|---|---|---|

| 1″ / 25mm | 185 | 93 | 55,000 | 60 |

| 1.5″ / 38mm | 138 | 94 | 16,000 | 58 |

| 2″ / 50mm | 121 | 95 | 5,500 | 45 |

| 3.5″ / 90mm | 40 | 97 | 1,180 | 30 |

Packaging & Delivery

- Standard Packaging: Plastic bags + cartons (custom options available).

- MOQ: Flexible, contact for bulk order discounts.

Why Choose Plastic VSP Rings?

- Cost-Effective: Lower energy consumption vs. metal packings.

- Customizable: Size and material tailored to your process needs.

- Eco-Friendly: Recyclable plastics reduce environmental impact.

Ideal for: Engineers seeking low-pressure-drop packing with high corrosion resistance.