Activated carbon is one of the most effective adsorbent materials used in modern purification systems. From drinking water treatment to industrial wastewater management, from food processing to air purification, activated carbon plays a critical role in creating safer, cleaner, and healthier environments.

1. What Is Activated Carbon?

Activated carbon, sometimes called activated charcoal, is a processed form of carbon that has been treated to create a network of highly porous structures. These pores give it an extremely large surface area (up to 1,500 m² per gram), enabling it to adsorb (trap and hold) unwanted substances from liquids and gases.

2. Raw Materials for Activated Carbon Production

The most common sources include:

- Coal-based carbon – anthracite, bituminous coal, or lignite

- Coconut shell carbon – renewable, hard, and high-density

- Wood-based carbon – softer, with larger pore distribution

Each raw material produces activated carbon with unique pore size characteristics, making it suitable for different applications.

3. How Activated Carbon Is Produced

The production of activated carbon involves two main stages:

- Carbonization: Heating the raw material in an oxygen-free environment to remove volatile compounds, leaving behind a carbon-rich structure.

- Activation: Treating the carbonized material with steam or chemical agents at high temperatures (600–1200°C) to develop micropores, mesopores, and macropores.

- Steam activation creates physical pores and is widely used for coconut shell and coal-based carbons.

- Chemical activation (using acids or bases) is more common for wood-based carbons and produces larger pores.

The final pore structure determines how well the carbon adsorbs different contaminants.

4. Types of Activated Carbon

Activated carbon can be classified in multiple ways:

1. By Form

- Powdered Activated Carbon (PAC): Very fine particles (<0.18 mm). Ideal for rapid treatment and short contact times (e.g., emergency water purification, food decolorization).

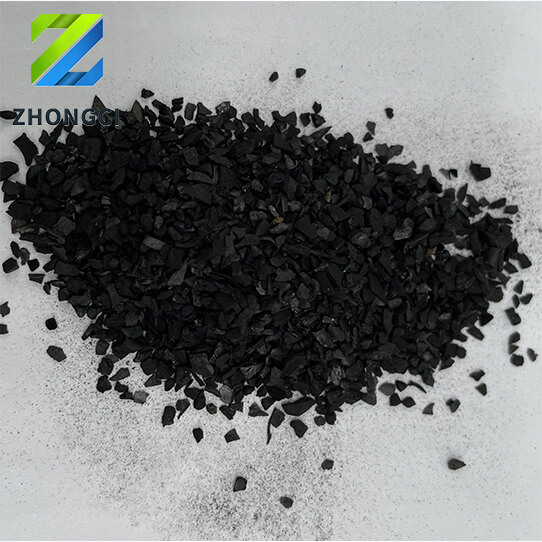

- Granular Activated Carbon (GAC): Larger particles (0.2–5 mm). Used in continuous filtration systems for drinking water, wastewater treatment, and aquariums.

- Extruded / Pelletized Carbon: Cylindrical shapes produced by compressing powdered carbon with binders. Highly durable, used in air filters and gas treatment systems.

2. By Raw Material

- Coconut Shell Activated Carbon: High microporosity, excellent for removing small molecules such as chlorine, VOCs, and disinfection by-products. Perfect for drinking water and air filters.

- Coal-Based Activated Carbon: Balanced pore distribution. Effective for industrial wastewater, chemical purification, and gas phase adsorption.

- Wood-Based Activated Carbon: Higher mesopore content. Common in decolorization applications such as sugar refining, pharmaceuticals, and beverage production.

5. Applications of Activated Carbon

Activated carbon is one of the most versatile purification materials available. Its uses include:

1. Water Treatment

- Municipal Drinking Water: Removes chlorine, pesticides, and organic pollutants.

- Wastewater Treatment: Adsorbs dyes, phenols, heavy metals, and industrial pollutants.

- Aquariums & Aquaculture: Improves water clarity, removes ammonia by-products, and enhances fish health.

2. Food & Beverage Industry

- Decolorization of sugar, syrups, and juices.

- Removal of odors and impurities in wine, beer, and edible oils.

3. Pharmaceuticals & Chemicals

- Purification of raw materials and intermediates.

- Removal of impurities during drug production.

4. Air & Gas Treatment

- Indoor air filters for odor and VOC removal.

- Industrial gas purification (removing hydrogen sulfide, sulfur compounds, and solvents).

- Cigarette and respirator filters.

5. Mining & Metallurgy

- Used in gold recovery through the Carbon-in-Pulp (CIP) and Carbon-in-Leach (CIL) processes.

6. Environmental Protection

- Soil remediation and spill cleanup.

- Adsorption of harmful organic compounds from contaminated sites.

6. The Importance of Iodine Value in Activated Carbon

The iodine value measures the adsorption capacity of activated carbon for small molecules. It is expressed in mg of iodine adsorbed per gram of carbon.

- 500–700 mg/g (Low Iodine Value): Larger pores, best for removing bigger molecules such as dyes and tannins.

- 800–900 mg/g (Medium Iodine Value): Standard grade for wastewater treatment and general filtration.

- 1000–1200 mg/g (High Iodine Value): High microporosity, excellent for drinking water purification, removing chlorine by-products, VOCs, and trace organics.

Example Applications by Iodine Value

- 700 mg/g Wood-Based Carbon: Used in sugar refining for decolorization.

- 900 mg/g Coal-Based Carbon: Applied in wastewater plants to remove phenols and industrial pollutants.

- 1100 mg/g Coconut Shell Carbon: Chosen for drinking water treatment and bottled water industries.

7. How to Choose the Right Activated Carbon

When selecting activated carbon, you should consider:

- Application Purpose: Drinking water, wastewater, air purification, food, or industrial use.

- Type of Contaminants: Organic molecules, chlorine, heavy metals, or VOCs.

- Required Iodine Value: Match adsorption capacity with purification goals.

- Form (PAC, GAC, Pellet): Depending on whether you need rapid adsorption or long-term continuous filtration.

- Regeneration & Cost Efficiency: Some activated carbons can be reactivated and reused, lowering costs.

👉 Case Study Example:

- A municipal water plant might choose coconut shell GAC with iodine 1100 mg/g to meet drinking water safety standards.

- A textile factory may select coal-based GAC with iodine 850 mg/g to adsorb dyes and wastewater chemicals.

- A sugar refinery often prefers wood-based PAC with iodine 600 mg/g for efficient decolorization.

https://chempacking.cn/wp-content/uploads/2024/10/1647252752678972.jpg

8. Why Choose Zhongci Environmental Ceramics Materials

At Zhongci Environmental Ceramics Materials, we specialize in supplying premium activated carbons for different industries. Our offerings include:

- Coconut shell, coal-based, and wood-based activated carbons

- Iodine values from 500 to 1200 mg/g to suit every purification need

- Forms available: Powder, granular, and pelletized carbon

We ensure consistent quality, professional consultation, and tailored solutions for your specific applications. Whether you are in water treatment, food processing, pharmaceuticals, air purification, or mining, we have the right activated carbon for you.

🌐 Learn more at: www.chempackings.com