Cooling Tower Fill Selection Guide — Materials, Structures, Applications and Optimization

Cooling tower fill is not a universal component, and selecting it correctly is essential for the stability, efficiency, and energy consumption of industrial cooling systems. This detailed article explains how to choose the right fill type, pattern, size, and material based on water quality, temperature, tower structure and working environment.

Incorrect selection results in clogging, inefficient heat transfer, tower deformation, energy waste, shutdowns, and high operating cost. Proper selection, however, ensures maximum temperature drop, lower power consumption, long lifespan, and lower maintenance cost.

1. Choosing Fill by Cooling Method: Film Fill vs Splash Fill

Cooling towers operate differently depending on their design. Therefore, choosing fill begins with identifying the tower type.

| Cooling Tower Method | Suitable Fill | Reason |

|---|---|---|

| Counter-flow tower | Film fill / High-density structured fill | Allows downward water + upward airflow contact with maximum heat exchange |

| Cross-flow tower | Cross-corrugated film fill | Supports side-flow air passage with low pressure drop |

| Heavy industrial cooling | Splash fill | Prevents blockage caused by impurities, oil, and suspended solids |

| High-temperature + gas cooling | Ceramic honeycomb fill | Withstands thermal shock and chemical corrosion |

If cooling efficiency is the only priority, film fill is usually the best.

If water quality is dirty, splash fill is required to avoid clogging.

If conditions are extreme, ceramic fill is the best long-term investment.

2. Selecting Fill by Water Quality and Contaminants

Water quality characteristics heavily influence fill performance.

| Water Quality | Visual Signs | Recommended Fill | Reason |

|---|---|---|---|

| Clean | Clear water, low dirt | PVC Film Fill | Provides highest heat transfer |

| High temperature | >65°C | PP Film Fill | Better mechanical strength and heat resistance |

| Dirty / sludge / sand | Sediments, algae, fibers | Splash Fill | Avoids clogging and maintains airflow |

| Oily or chemical | Industrial wastewater | Splash Fill or Ceramic Fill | Oil blocks film fill and accelerates wear |

| Corrosive / acid / flue gas | Chemical fumes + water | Ceramic Honeycomb Fill | Absolute corrosion resistance |

⚠ Many users mistakenly choose film fill for dirty industrial water, leading to rapid blockage and shutdown.

Water quality must be evaluated before purchase.

3. Selecting Fill by Temperature and Operating Load

Temperature and operating intensity determine lifespan.

| Operating Condition | Suitable Fill |

|---|---|

| Continuous HVAC cooling | PVC Film Fill |

| High-load 24-hour industrial operation | PP Film Fill |

| Cooling tower with high hot water inlet temperature | PP Film Fill |

| Tower exposed to flue gas, chemicals or high temperature | Ceramic Honeycomb Fill |

Ceramic fill is not damaged by heat, corrosion, solvent, or humidity — it is the only choice for power plants and petrochemical industries.

https://chempacking.cn/wp-content/uploads/2024/10/1643267793661927.jpg

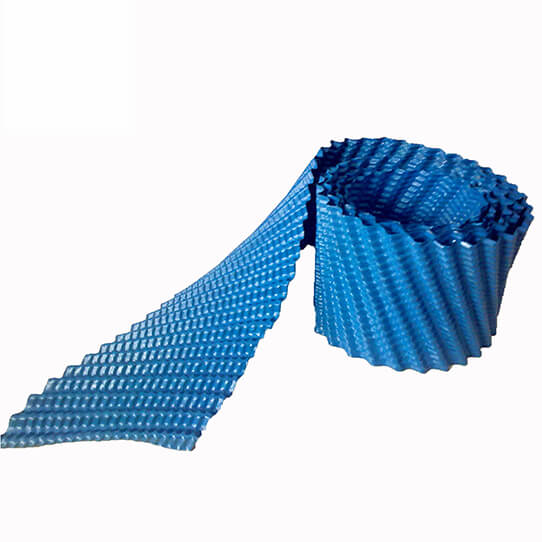

4. Fill Size and Pattern — Affects Efficiency and Clogging Resistance

Choosing the right pattern is just as important as choosing the material.

| Pattern | Features | Best Use |

|---|---|---|

| High-density corrugated film | Max contact area | Clean water cooling |

| Medium-density corrugated film | Balance of heat transfer & anti-clogging | Industrial water |

| Large spacing corrugated film | Lower pressure drop | Dusty industrial environment |

| Vertical wave film | Fast water drainage | High-temperature PP systems |

| Splash bar / grid type | No clogging | Wastewater & steel plants |

| Ceramic honeycomb cell | Ultra-long lifespan & chemical resistance | Power / chemical / refinery industries |

Correct pattern selection ensures stable heat transfer even after years of use.

5. Fill Thickness — Strength vs Efficiency Balance

- 0.25–0.30 mm → Economic & efficient (clean water only)

- 0.30–0.35 mm → Balanced (most factory systems)

- 0.40–0.60 mm → Heavy duty (high temperature / industrial)

- Ceramic fill → High structural strength, cannot deform

If the fill is too thin, it will collapse under water load and cause tower shutdown.

If the fill is too thick, heat exchange performance decreases.

Zhongci helps customers select optimal thickness based on tower design and water load.

6. Replacement and Upgrade Strategy for Old Cooling Towers

Many customers use tower renovation to greatly improve cooling performance.

| Existing Condition | Recommended Solution |

|---|---|

| Old PVC sheets softened and bent | Upgrade to PP film |

| Repeated clogging | Convert to splash fill |

| Corrosion due to chemicals | Convert to ceramic fill |

| Temperature drop insufficient | Higher-efficiency corrugated film |

| Limited maintenance time | Modular fill blocks for fast installation |

Upgrading fill is the fastest, most effective and least expensive way to increase cooling tower performance.

7. Why Zhongci Cooling Tower Fill Performs Better

Zhongci Environmental Ceramics Materials provides:

✔ High-grade PVC / PP polymer and industrial ceramic

✔ Imported anti-aging reagents and UV-resistant formulation

✔ High-precision thermo-forming and sintering technology

✔ Strong tensile strength and deformation resistance

✔ OEM support — customized size, thickness, spacing, cell structure

✔ Global export and engineering technical support

Our fill is designed for industrial durability — not household quality.

Final Advice From Experts

Before purchasing fill, always confirm:

- Water quality (clean / dirty / oily / corrosive)

- Inlet water temperature range

- Tower type (counter-flow / cross-flow)

- Operating load per year

- Whether the tower needs replacement or upgrade

Providing these details allows Zhongci engineers to recommend the exact optimal configuration — without overspending.

Contact for Technical Selection and Quotation

Zhongci Environmental Ceramics Materials

🌐 www.chempackings.com

📞 Whatsapp: +86 135 7645 4821

Free services available:

- Fill selection based on water quality and temperature

- Volume and quantity calculation based on tower drawing

- Custom design for industrial projects and OEM brands

- Global shipping support