Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

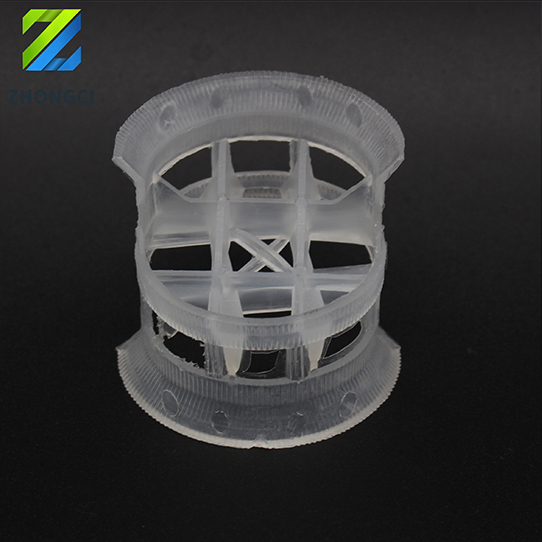

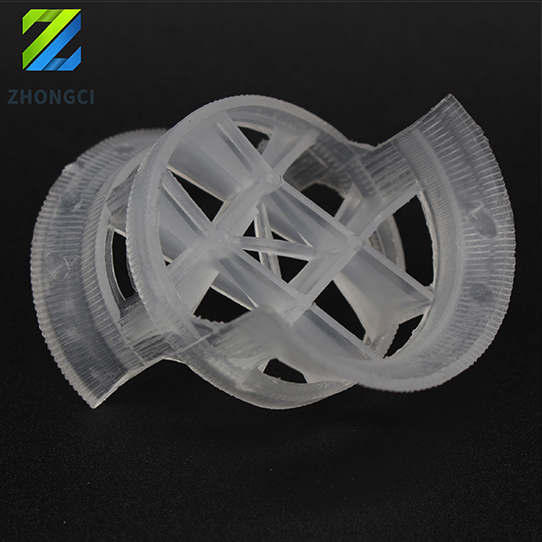

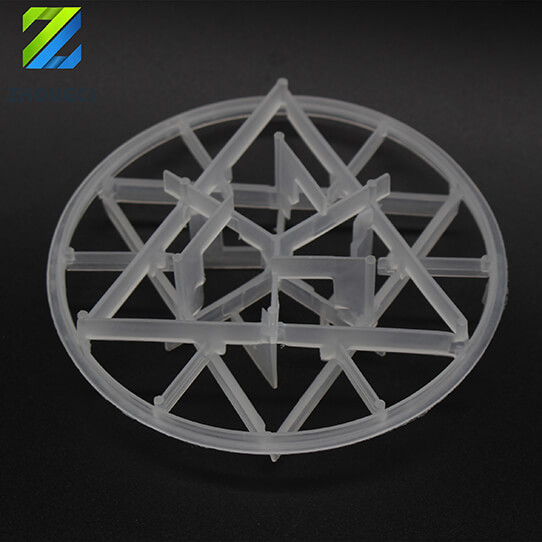

Plastic conjugate ring

Plastic conjugate ring is also called plastic conjugate ring packing. It integrates the advantages of the annular random packing and plastic intalox saddle ring. Due to its special inner structure, plastic conjugate ring has more contacting points and larger gas-liquid contacting surface than traditional random packings. This product has many advantages, such as large flux, low fluid resistance and good operating flexibility.

Specifications Plastic conjugate ring:

Plastic conjugate ring can be made from various heat and corrosion resistant materials, such as reinforced polypropylene, chlorinated polyvinyl chloride and polyvinylidene fluoride. Therefore, this type of plastic random packing has good chemical corrosion resistance and long service life. It is widely used in sulfuric acid absorption, formic ester distillation, methylacrylic acid treatment, exhaust gas purification, eucalyptus oil purification and water purification.

Material of Plastic conjugate ring

Plastic tower packing can be made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinyiidene fluoride (PVDF) and Polytetrafluoroethylene (PTFE). The temperature in media ranges from 60 Degree C to 280 Degree C

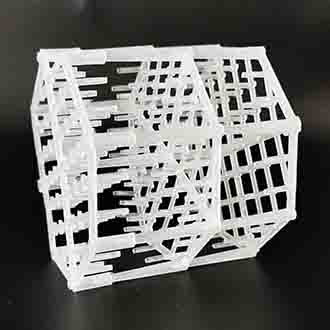

Plastic Tower Packings: plastic pall ring, plastic saddle, plastic super saddle, plastic cascade ring, plastic conjugate ring, plastic teller rosette ring, plastic hi-flow ring, plastic snowflake ring, plastic VSP ring, plastic tri-pack, etc.

Physical & chemical properties of plastic Random Packing:

| Performance / Material | PE | PP | RPP | PVC | CPVC | PVDF |

| Density (g/cm3) | 0.94-0.96 | 0.89-0.91 | 0.93-0.94 | 1.32-1.44 | 1.50-1.54 | 1.75-1.78 |

| Operation Temp.(oC) | 90 | >100 | >120 | >60 | >90 | >150 |

| Chemical corrosion resistance | Good | Good | Good | Good | Good | Good |

| Compression Strength(Mpa) | >6.0 | >6.5 | >7.0 | >6.0 | >8.0 | >10.0 |

● Lifespan: more than 3 years.

● Package: plastic bags, cartons.

Table 1: The Technical Parameter of Plastic Conjugate Ring | ||||||

Item | Size | Surface Area | Voidage | Bulk Number | Bulk Density | Dry Packing Factor |

PCRT-01 | 25 × 25 × 1.0 | 185 | 95% | 74000 | 96 | 216 |

PCRT-02 | 37 × 37 × 1.5 | 142 | 91% | 16320 | 57.7 | 168 |

PCRT-03 | 50 × 40 × 1.5 | 104 | 80% | 9500 | 52 | 164 |

PCRT-04 | 76 × 76 × 2.6 | 81 | 95% | 3980 | 64.8 | 94 |

PCRT-05 | 100 × 100 × 2.0 | 55 | 96% | 1850 | 48 | 62 |

Features:

·Large flux.

·Low fluid resistance.

·Good corrosion resistance.

·High mass transfer efficiency.

·Low cost.

Applications:

·Applied in desulphurization and decarburization applications.

·Applied in sulfuric acid absorption, formic ester distillation and methylacrylic acid treatment.

·Used in exhaust gas purification, eucalyptus oil purification and water purification.

·Used in scrubbing tower, cooling tower and purification tower, etc.