Exhibition

How to Select the Right HDPE Ball for Your Application?

Zhongci Environ …

How to Optimize MBBR Systems? Choose HDPE 31x1mm Filter Media

1. HDPE 31x1mm …

Unlock Higher Cooling Efficiency with the Right Fill Design

Cooling Tower F …

Cooling Tower Fill Media — Complete Explanation and Use Cases

Cooling tower f …

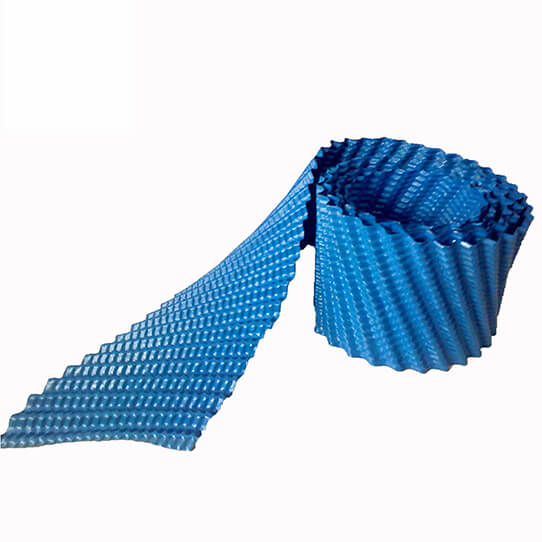

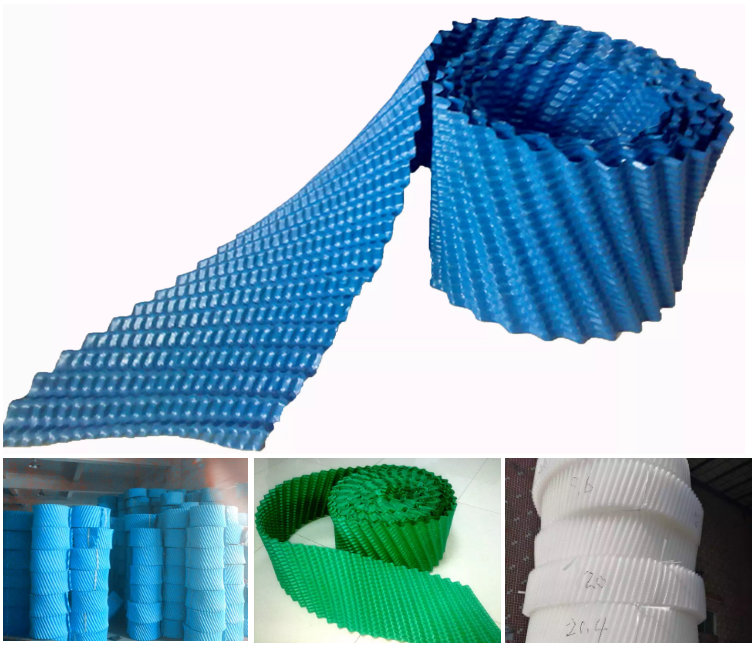

PVC Round cooling tower fills

The round counterflow cooling tower fill is also called “obliquely staggered cooling tower fill”, it is made from modified flat PVC sheets through hot-pressing processing. The role of the water-spraying fill is to transfer the hot water needs to be cooled into water drops and to mold the water film, so as to increase the contact area and time of water and air, i.e., increase the heat transfer intensity of water and air.

The cooling process of water mainly occurs in the water-spraying fill, where the heat transfer and mass transfer of water and air occur. The cooling effect of cooling tower depends on the heat transfer performance of the water-spraying fill to a very large extent. The water-spraying fill with good performance owns quite good heat dissipation capability.

The obliquely staggered fill has advanced technology, reasonable design, reliable data, and durabilities.

According to the test and long-term operation, the cooling effect is very good, and it owns such advantages as small ventilation resistance,strong hydrophilia, large contact area, etc. The inclination angle usually is 60 degrees, and it is mainly applied to the round counterflow cooling tower

Name | Wholesale PP PVC round Cooling Tower PVC Fill |

Material | PVC, PP |

Nomal Size | 200mm/225mm/240mm/250mm/300mm/340mm |

Fluted size | 19mm/25mm |

Shaping mode | Plastic extrusion mould |

Sheet thickness | 0.2-0.5MM ,also can be customized |

Packing Details | n bundle, wooden pallet or as requested |

Sample Time | 1-2days |

Production Date | Within 15~20days |

Color | Black/Blue/Green/Transparent |

Operating temperature | -20℃~65℃ |

Details Images

Recommend Products

Manufacturing Technique